Automatic Filter Paper Slitter Rewinder Machine

Products Description

The main electric control system adopts center computer control(PLC), person-machine interface operation, dynamic display. Equipped with PLC and touch screen, all the parameter are displayed on the monitor. You only need to setup the material roll diameter and thickness, the PLC will give a proper parameters for machine running automatically.

Application

It is suitable for slitting and rewinding all kinds of paper, film, copper foil, aluminum foil and other materials.Such as PVC, PE, PET, adhesive tape,release paper and other materials.

Performance and Features

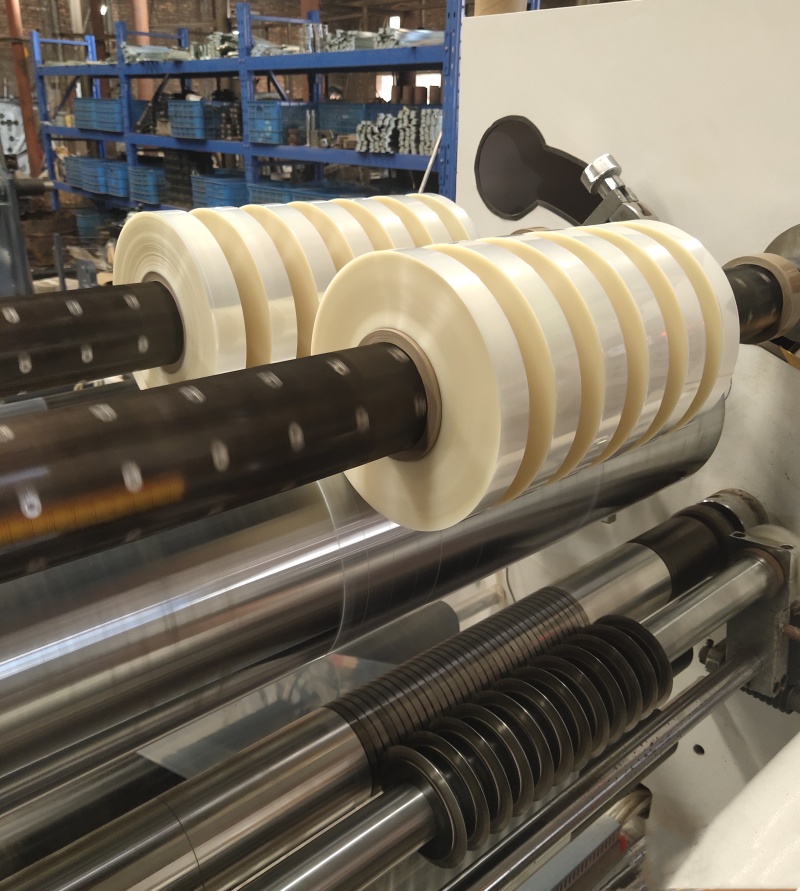

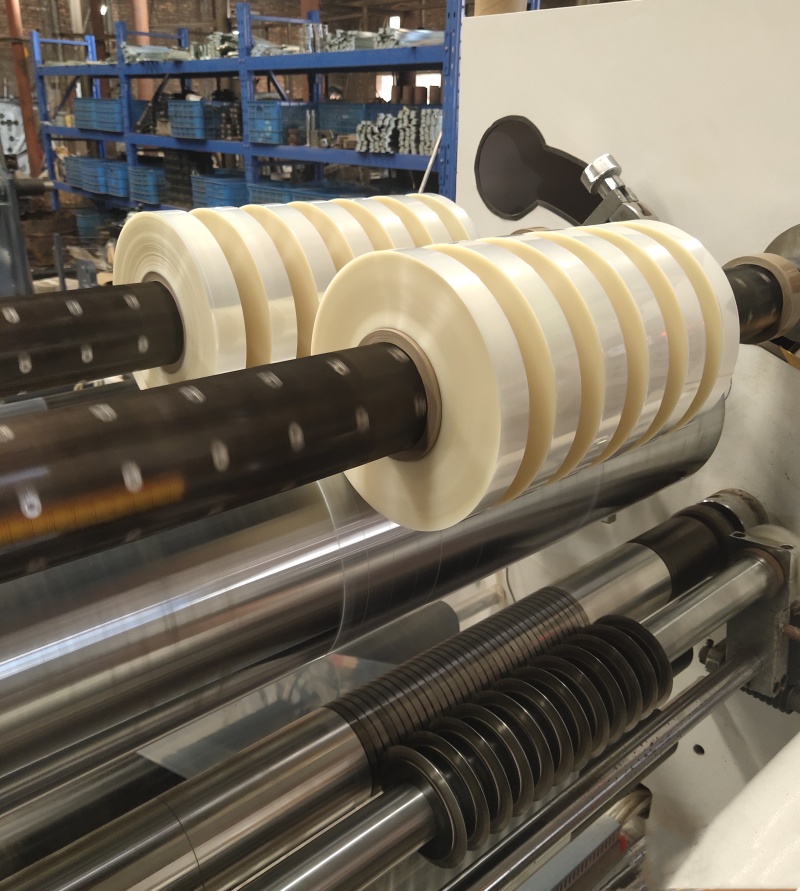

1. The machine adopts the method of center coiling and surface contact and coiling.

2. Automatically record meters, alarm and other functions.

3. The rewinding adopts A, B and air-expansion shaft structure, which is convenient for loading and unloading.

4. The unwinding adopts the photoelectric automatic deviation correction system, so that the irregular material can be cut normally.

5. Flat knife slitting waste edge automatic discharge device.

6. Automatic feeding, equipped with air expansion shaft (3 inches).

Technical Parameter

Raw material width | 700-1600mm |

Maximum raw material diameter | 1000mm |

reel | Split tension inflatable shaft |

Maximum winding diameter | 600mm |

total power | 5.5-7.5KW |

Minimum slitting width | 5mm |

Slitting speed | 150m/min |

Diameter of unwinding shaft | 3 inch |

Diameter of winding shaft | 3 inch |

Dimensions | 2450×2450×1550mm |

weight | 3000-6000kg |

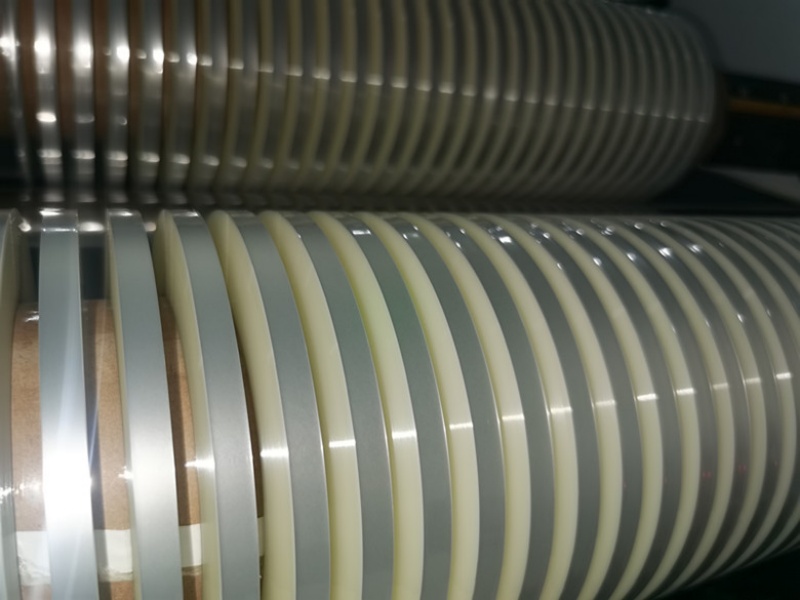

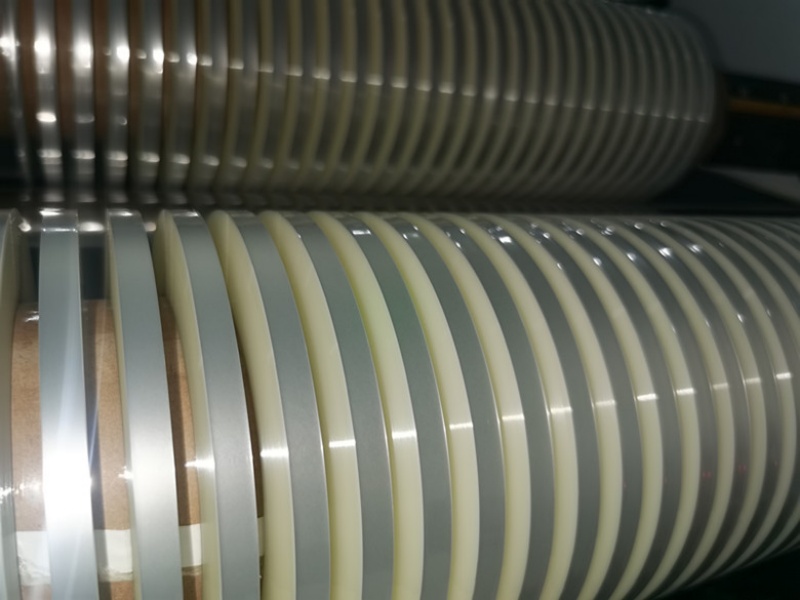

Slitting effects

In the world of manufacturing and production, efficiency is key. One of the most important pieces of machinery for achieving high levels of efficiency is the automatic slitting machine. This piece of equipment is invaluable for businesses that need to cut large rolls of material into smaller, more manageable pieces. Here are just a few of the advantages that come with investing in a high-quality automatic slitting machine.

1. Improved Speed and Accuracy

One of the biggest advantages of an automatic slitting machine is the speed and accuracy it provides. With automated controls and precision cutting blades, these machines are able to quickly and efficiently cut through large rolls of material with ease. This results in a significant reduction in the time and labor required for manual cutting and processing, while also improving the accuracy and consistency of the cuts.

2. Versatility

Another major advantage of an automatic slitting machine is the versatility it provides. With the ability to cut a wide range of materials, including paper, plastic, and metal foils, these machines offer businesses the flexibility they need to adapt to changing production needs. Additionally, they can be configured for different widths, thicknesses, and shapes, making it easy to produce custom-cut pieces that meet specific requirements.

3. Reduced Waste

Another significant benefit of an automatic slitting machine is the reduction in waste. With precise cutting and automated controls, these machines minimize the risk of human error, resulting in fewer mistakes and less material waste. Even small reductions in waste can have a significant impact on a business's bottom line, both by reducing the cost of raw materials and by freeing up valuable production time and resources.

4. Improved Safety

Along with the numerous efficiency benefits, automatic slitting machines also provide improved safety for workers. By automating the cutting process, these machines remove the need for manual cutting, which can be dangerous and cause injury to workers. This reduces the risk of accidents and injuries, helping businesses to maintain a safe and healthy work environment.

In conclusion, an automatic slitting machine is an essential piece of equipment for any business that needs to process large volumes of materials quickly and efficiently. With its speed, accuracy, and versatility, along with the reduced waste and improved safety it provides, investing in one of these machines can have a significant impact on the success and profitability of a business.