Function of Aluminum Foil Roll Cutting Machine

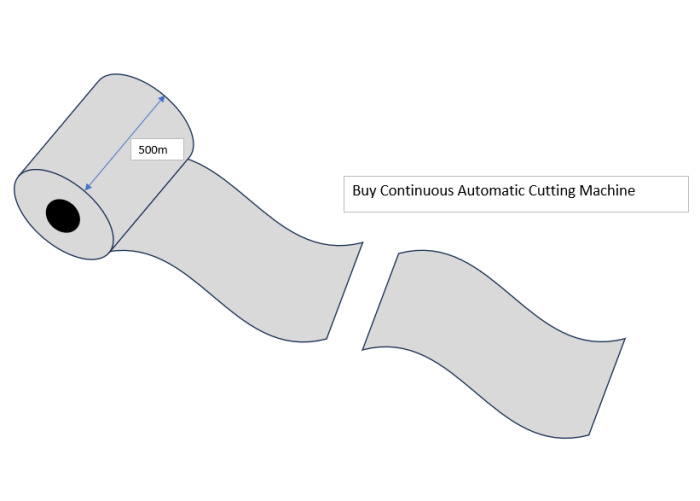

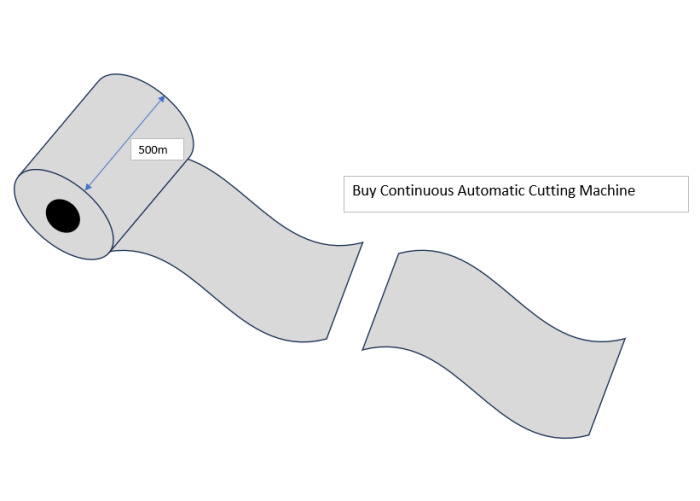

Sheet cutting aluminum foil, copper foil, PET, PC, PVC, PCB, FPC, Lithium battery film, flannelette, metal foil and all kinds of paper and non metal materials in roll form. To cut material from rolls to sheets as below photo.

Advantage of Aluminum Foil Sheet Cutting Machine

1. Aluminum foil is one of the most widely used packaging materials in the world. From food and beverage wrapping to industrial products and pharmaceutical packaging, aluminum foil plays a crucial role in ensuring the safety and hygiene of the products. However, the process of cutting aluminum foil can be time-consuming and labor-intensive, which is why the aluminum foil slitting machine has become an essential piece of equipment in packaging industries. Here are some of the advantages of using an aluminum foil slitting machine in your business.

2. Accuracy and Precision

Aluminum foil roll cutting machines are designed to accurately and precisely cut aluminum foil into the desired size. These machines use advanced technologies such as rotary blades, laser-guided cutting, and digital control systems to ensure that the cutting are uniform, consistent, and free from any defects or imperfections. This level of precision and accuracy is particularly important when dealing with sensitive products that require specific packaging dimensions.

3. High Production Speeds

An aluminum foil roll cutting machine can significantly improve the production efficiency of your business. Unlike manual cutting, which is slow and labor-intensive, an aluminum foil slitting machine can process large volumes of aluminum foil in a short period. The machine is designed to work continuously, with minimal downtime, which means you can produce more outputs in a shorter time frame.

4. Cost-Effective

By investing in an aluminum foil roll cutting machine, you can reduce labor costs and improve the overall efficiency of your business. The machine is designed to work continuously and does not require frequent maintenance or repairs, which reduces downtime costs. Additionally, the machine is energy-efficient, which means you can save on electricity costs in the long run.

5. Improved Safety and Hygiene

Aluminum foil roll cutting machines are designed to meet the highest safety and hygiene standards. The machine is equipped with safety features such as emergency stop buttons and guardrails to prevent accidents and injuries. Additionally, the machine is constructed with high-quality materials that are corrosion-resistant and easy to clean, ensuring that the end product is safe and hygienic for the end-user.

In conclusion, investing in an aluminum foil roll cutting machine is a smart choice for any business that deals with aluminum foil packaging. The machine offers numerous advantages, including accuracy, precision, high production speeds, cost-effectiveness, versatility, and improved safety and hygiene. By incorporating an aluminum foil slitting machine into your production line, you can improve your business's efficiency, productivity, and profitability in the long run.

Machine configuration

1. Cutting Blade

Material : SKD-11. Lifetime : About 1 Million times cuts. Scissor-type cutting blade, durable with highest hardness 65 HRC. Easy to adjust, sharp, maintain and change. Warranty: This is spare part, due to consumable parts.

2. Touch Screen

You Can Set All Parameter In Touch Screen , The Length ,Batch Quantity, Total Quantity ,Cutting Speed ,Etc. It's Convenient For Workers To Operate The Machine.

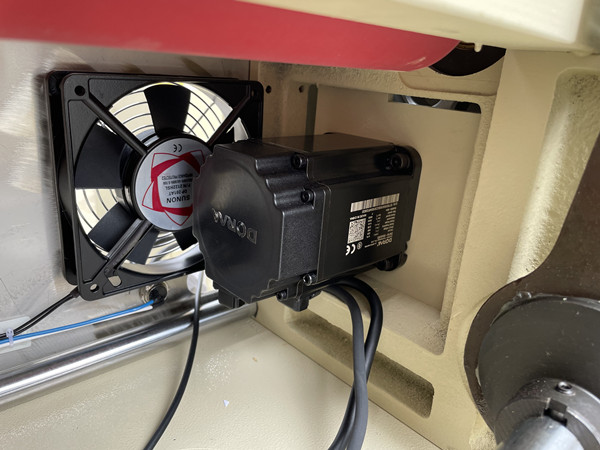

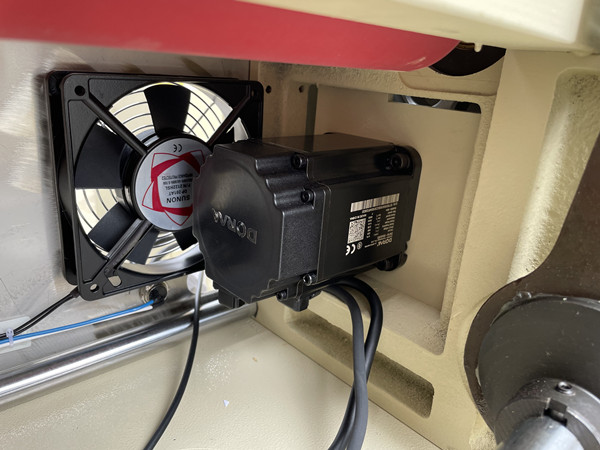

3. 2 Pcs Servo Motors

This machine is equipped with 2 pcs Servo motors control. They are cooperated with feeding roller, make sure the cutting precision and feeding precision could reach 0.03 mm.

4. Automatic Unwinding Device

Material Unwinding Stand For Automatic Roll To Sheet Cutter, It Supports Max 300kg Material Roll.

Machine Features

1. The max width: 360, 500, 600, 700, 1000, customized

2. Precision: 0.02mm

3. Material thickness: 0.5mm-20mm

4. Cutting speed: 100 cut/min

5. Both kiss-cut and complete cut are available

6. Complete cut is for standard machine, and kiss-cut is an option

7. A conbination of PLC and servo motor

8. Eye mark device for optional

9. An air shaft as the loading shaft

10. Two accessories, static eliminator and conveyor belt, for you to choose

11. Automatic unwinding function

12. Cutting length is accurate

13. Operation is easy

14. Waste rate is low

15. Diverse functions satisfy your various requirements

16. We offer superior-quality products and best service for you

17. As a high-tech manufacturer, we possess veteran engineers and professional sales team

FAQ

Q1: Are you factory or trading company?

A1: We are machine manufacturing factory.

Q2: How does your factory do quality control?

A2: We have profession engineers' team to prove and ensure machine quality.

Q3: Machine warranty?

A3: two year since machines arrived your port.

Q4: What's your delivery time?

A4: Normally, it need 15 to 25 working days since get the deposit.

Q5: How do you keep the after-sales service?

A5: We do business based on faith, we insist on " quality is the first and most important" . We will carefully check the material, produce, test and adjust machine, we have oversea technician service,to help you install the machine.

Q6: Where's your company located? how can we visit?

A6: Our company located in Yancheng city, Jiangsu province, if you take by flight can fly to Nanyang airport, , and also can by train from Shanghai to my city Yancheng train station directly.

Q7: What's the payment method?

A:We can accepted T/T,L/C, etc..