Efficiency and Automation:

This cutting machine revolutionizes the manufacturing process of non-woven fabric sheets. Its fully automatic operation minimizes manual intervention, significantly increasing production efficiency and reducing labor costs. The machine’s precise control systems ensure consistent and accurate cuts, eliminating errors and waste.

Cutting Precision and Versatility:

Equipped with advanced servo motor control and high-precision cutting blades, this machine delivers exceptional cutting accuracy. It can handle a wide range of non-woven fabric types and thicknesses, making it versatile for various applications, including medical supplies, hygiene products, and home furnishings.

User-friendly Interface and Operation:

The machine features a user-friendly interface with a touch screen control panel, allowing for easy operation and adjustments. Operators can effortlessly program and monitor cutting parameters, ensuring optimal performance and efficiency.

Reliability and Durability:

Constructed with high-quality materials and precision engineering, this cutting machine is built to last. Its robust design withstands the demands of continuous operation, ensuring reliable performance and longevity.

Safety Features:

Priority is placed on operator safety. The machine is equipped with multiple safety features, including emergency stop buttons, safety guards, and automated shut-off mechanisms, ensuring a secure working environment.

Customization and Adaptability:

Longterm Machinery understands that every business has unique needs. The Automatic Non-woven Fabric Sheet Cutting Machine can be customized to meet specific requirements, including cutting sizes, shapes, and production volumes.

Cost-effectiveness and Return on Investment:

Investing in this cutting machine offers long-term cost savings. Its efficiency and accuracy reduce material waste, while its durability minimizes maintenance and downtime. This translates into a higher return on investment and improved profitability for your business.

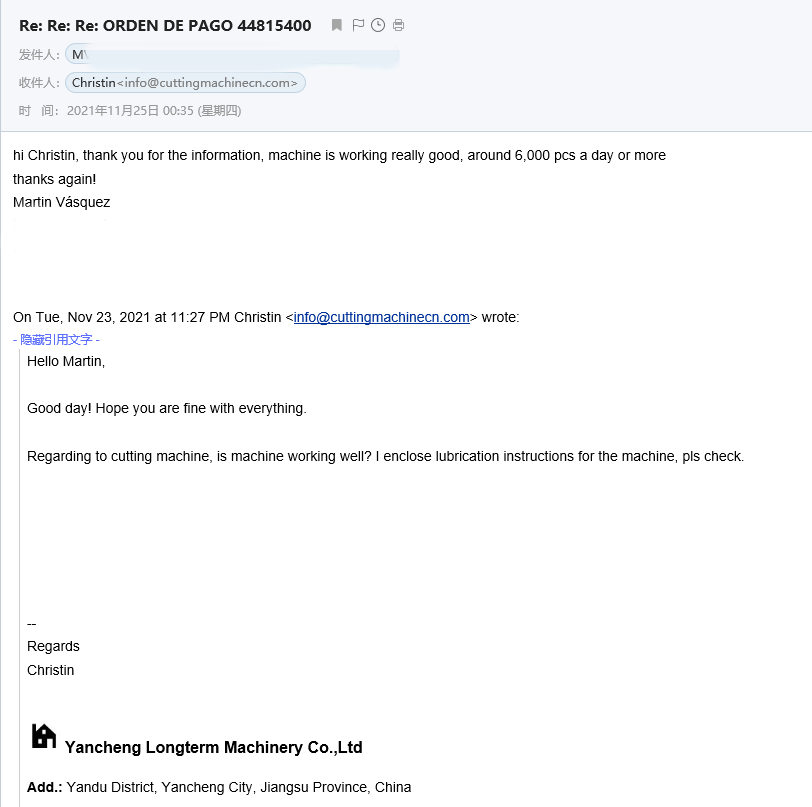

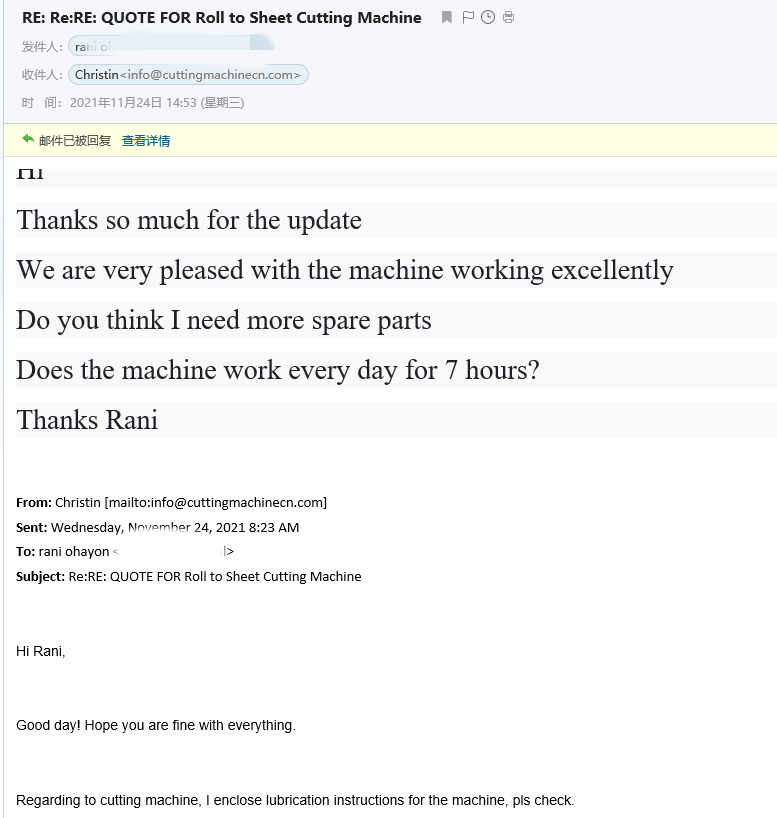

Global Support and Service:

Longterm Machinery provides comprehensive after-sales support and service, ensuring that your machine operates smoothly and efficiently. Their experienced team of technicians and engineers is available to assist with installation, training, maintenance, and repairs.

Choose the Automatic Non-woven Fabric Sheet Cutting Machine for Unparalleled Performance and Reliability:

Experience the benefits of automation, precision, and efficiency with Longterm Machinery’s Automatic Non-woven Fabric Sheet Cutting Machine. This cutting-edge technology will elevate your production capabilities and help you achieve success in the competitive non-woven fabric industry.