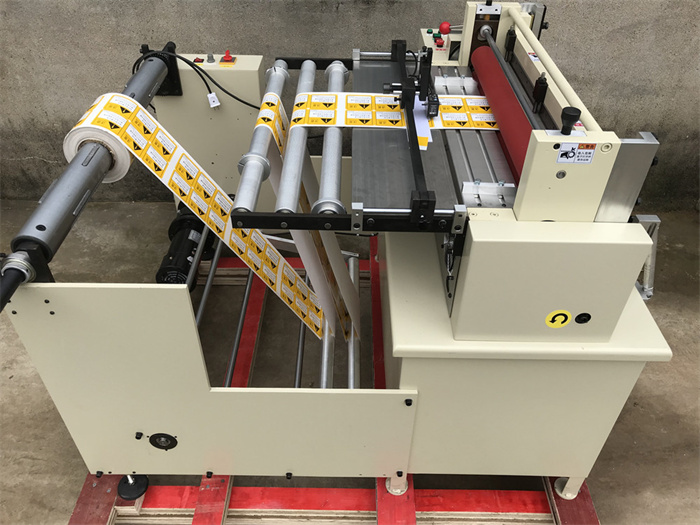

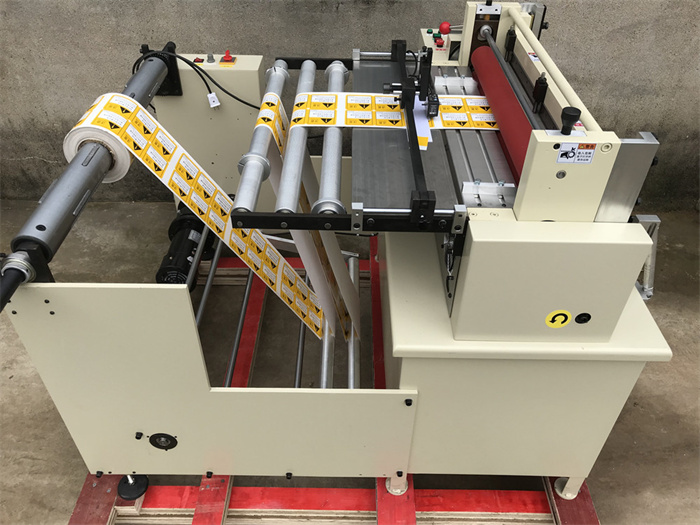

Automatic Roll To Sheet Cutting Machine

Automatic roll to sheet cutting machine adopts imported PLC touch screen operation control, easy operation and convenient and high precise cutting. Achieve automatic cutting from roll to sheets. Automatic roll to sheet cutting machine is to cut materials from rolls to sheets. Set cutting length and cutting quantity in touch screen as you need.

It is cutting materials like paper, printed material, conductive fabric, foam, diffuser, reflector film, double-sided adhesive tape, nickel plate, PET, PC, PE insulation paper, copper /aluminum foil and all kinds of adhesive tapes.

Automatic roll to sheet cutting machine advantages

1. We are specialized in roll to sheet cutting machine. We are the real manufacturer, not trading company.

2. We use the latest Mitsubishi PLC control in reel to sheet cutting machine.

3. We use Taiwan's newest WEINVIEW touch screen.

4. We use the latest servo motor control. We use 2 servo motors for the cutter and feeder. Precision is within 0.03mm.

5. We use a 40mm thick cast iron body, which will not be deformed for more than ten years and has higher accuracy. You must know CNC processing machines are all cast iron bodies, which will not be deformed for a long time.

6. Our sheet cutter machine structure is stable. For unwinder, it is connected with machine that can stand 300kg roll weight. It is automatic unwinding by motor.

Technical Parameters

Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Features Of automatic roll to sheet cutting machine

1. Cutting width: 360mm, 500mm, 600mm, 700mm, 1000mm.

2. Cutting length precision: 0.03mm

3. Material thickness: 0.5mm-20mm

4. Cutting speed: 0-100cut/min;

5. Both kiss-cut and complete cut are available;

6. Eye mark device for optional

7. An air shaft as the loading shaft;

8. Two accessories, static eliminator and conveyor belt, for you to choose;

9. Operation is easy;

10. Waste rate is low;

Automatic roll to sheet cutting machine photos

Why you need to choose automatic roll to sheet cutting machine?

1. Time-Saving: Roll to sheet cutting machine have high processing capacity, which translates to high production volume. With the machine's ability to cut quickly and continuously, production time is reduced, and more products are processed within a shorter time frame. This saves time and increases productivity.

2. Enhance Safety: Roll to sheet cutting machines have safety features that minimize risks of accidents in the workplace. They come with safety guards and interlocked safety switches that prevent accidental injuries during operation. Operators can work safely without risks to their hands or other body parts.

3. Easy to operate: Roll to sheet cutting machines are easy to operate and require little or no special training. Once the operator gets familiar with the slicer's controls and settings, they can quickly handle its operation without much difficulty.

4. Durable: Industrial slicers are built from high-quality materials such as stainless steel, making them more durable and robust. This increases their lifespan, reduces maintenance costs, and ensures that they serve the intended purpose for many years.

FAQ

1.Are You A Factory Or A Foreign Trade Company?

We are the real factory with more than 10 years experience.

2.If I Know Nothing About Automatic Roll to Sheet Cutting Machine, Which Model Should I Choose?

Please tell us your materials, width, thickness then we will provide you professional suggestions.

3. If I Do Not Know How To Operate The Automatic Roll to Sheet Cutting Machine, How You Can Help Me?

First, we have detailed user manual and videos for your learning. Second, our engineers will provide you technical support in time. If you want, we can provide you training in our factory or your door.

4.How About The Shipping Cost?

Sea transportation, LCL is OK. We have a shipping company that has cooperated for many years, which can help you save costs.

5.How About The Payment?

T/T,30% deposit, and 70% balance is after the production is finished and before delivery.