Automatic Vertical Plastic Film PE BOPP Slitting Rewinding Machine

Application

This slitting machine is suitable for slitting and rewinding many kinds of roll materials, such as PP, OPP, BOPP, PET, PVC and different kind of paper, kraft paper, food paper, etc.

Slitting machine technical parameters

| Model | LT-1600F |

| Max. unwind mother roll diameter | 600mm |

| Max. unwind mother roll width | 1300mm |

| Paper inner diameter | 76mm |

| Slitting width | 20-1600mm |

| Machine speed | 160m/min |

| Slitting speed | 150m/min |

| Max rewind diameter | 500mm×2 rolls |

| Rewind shaft diameter | 1" ,2" ,3"(standard 3", 2pcs install) |

| Slitting precision | ±0.5mm |

| Voltage | customized |

| Total power | 5.5-10KW |

| Gross Weight | 1000-2500kg |

| Overall dimension | 2.6×1.7×1.5m |

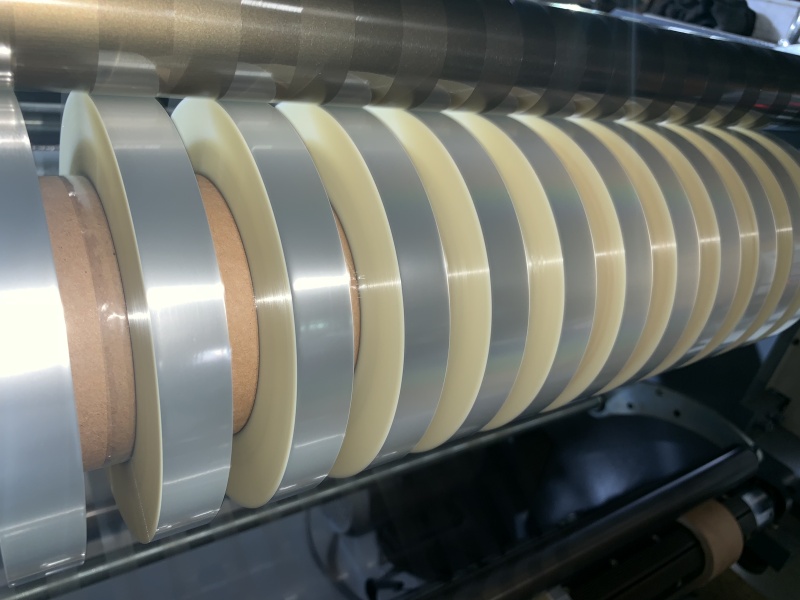

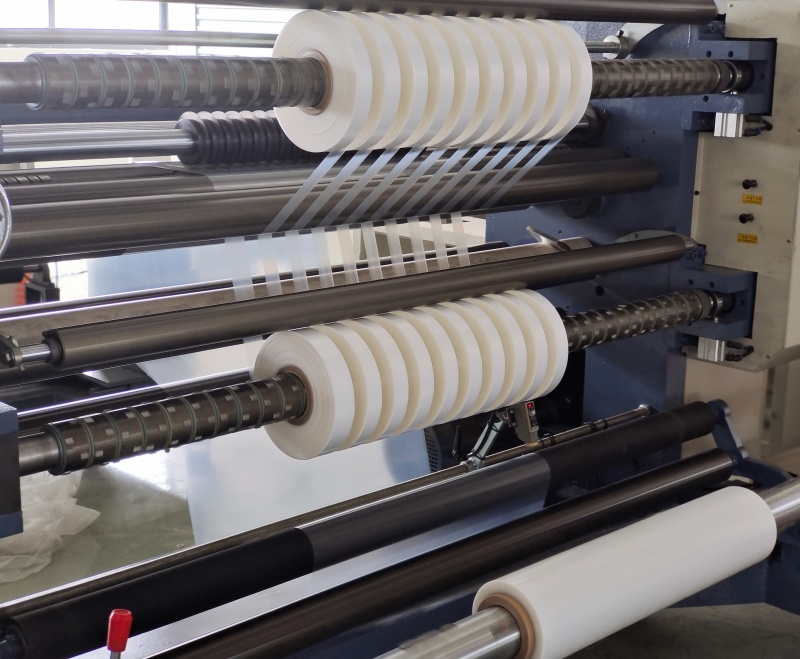

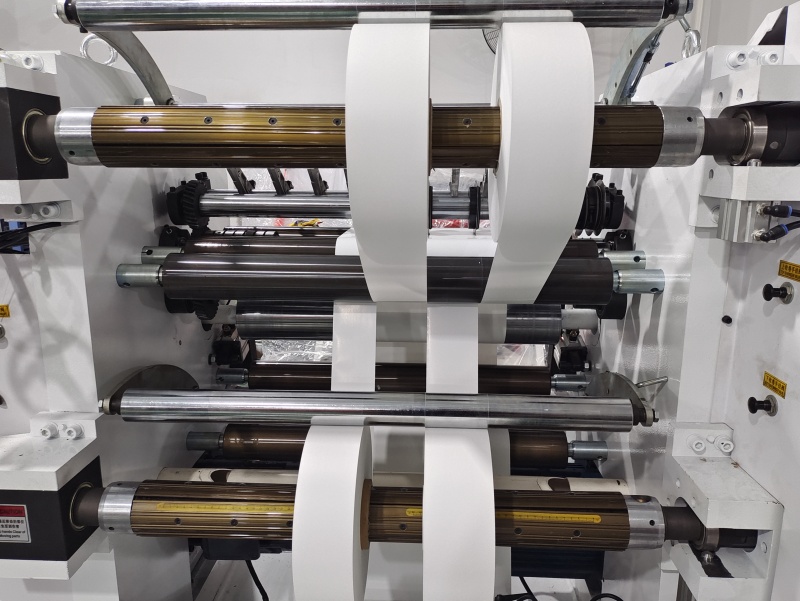

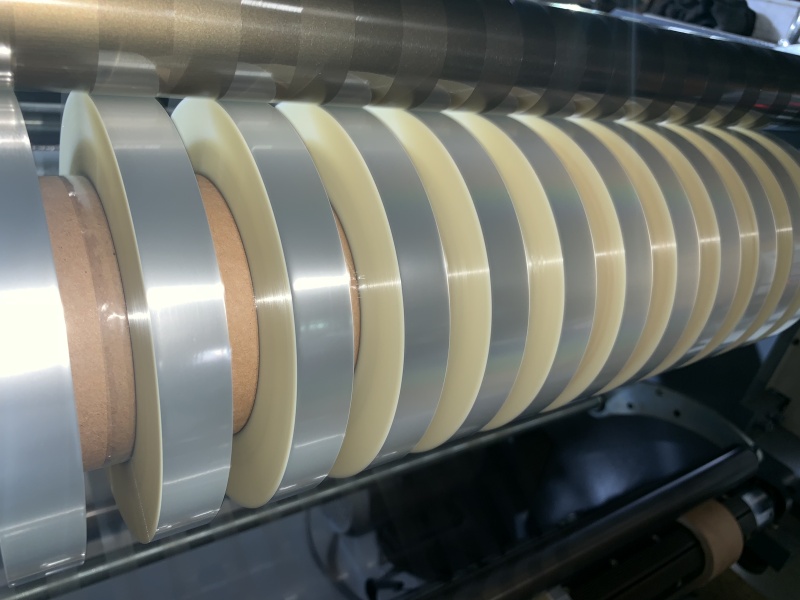

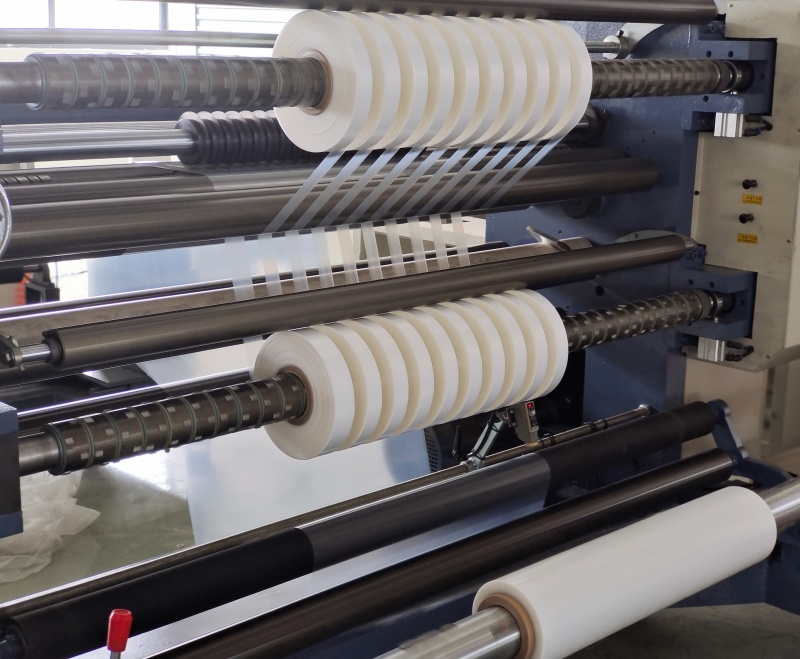

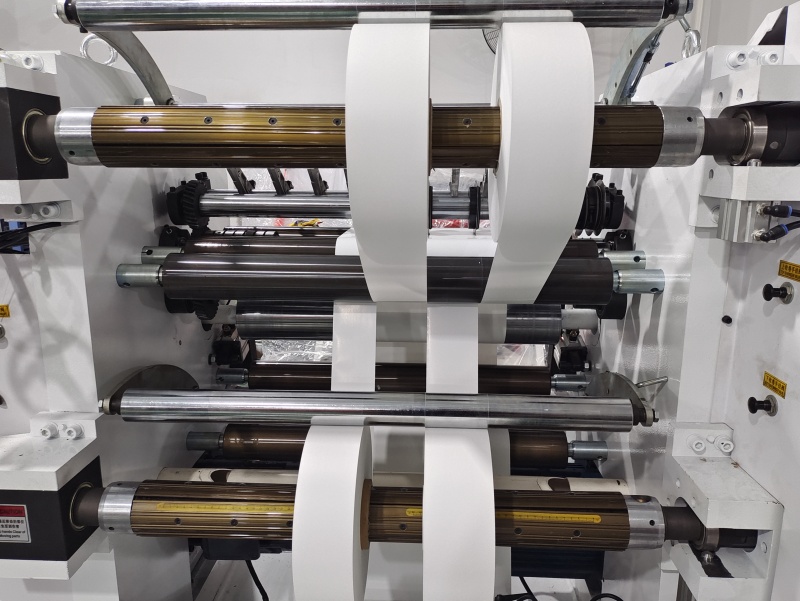

Based on good quality of slitting machine, the effect is pretty good. Pls see below photos.

There are options of slitting blades and rewinding shafts.

For slitting blades:

1. Round slitting blades

2. Straight slitting blade

For rewinding shafts

1. standard air shaft

2. Slide spindle

The evolution of Fully Automatic Slitting and Rewinding Machines

The process of slitting and rewinding is a crucial step in the production of various materials such as paper, plastic films, and non-woven textiles. The machines used for this process have undergone significant developments to improve their efficiency and accuracy. Of these machines, the fully automatic slitting and rewinding machine has emerged as the most advanced type in recent years.

The development of fully automatic slitting and rewinding machines can be traced back to the early 20th century. At that time, slitting machines were primarily used in the paper industry. These machines were manually operated and required skilled workers to carry out the process. This was a slow and tedious task, and the speed and accuracy of the cuts were often inconsistent.

As technology advanced, the manual process was replaced by semi-automatic machines that could be operated by a single person. The development of electric drives and the use of servo motors further improved the accuracy and efficiency of these machines.

In the 1990s, the first fully automatic slitting and rewinding machine was introduced in the market. These machines were capable of automatically loading and unloading the material, cutting it at high speed, and then rewinding the cut material. The introduction of programmable logic controllers (PLCs) made it possible to set the parameters for the machine and monitor the entire process.

Further advancements in technology have resulted in the development of fully automatic slitting and rewinding machines that are capable of producing finished products with high precision and accuracy. These machines use sensors and cameras to detect defects and make corrections in real-time. They are also designed for maximum efficiency, with high-speed cutting and rewinding capabilities that can handle a wide range of materials.

In summary, the evolution of fully automatic slitting and rewinding machines has come a long way from manual operations to the highly advanced machines we have today. These machines are critical to the production of various materials, and their continued development ensures that they will remain an essential part of modern manufacturing processes in the future.