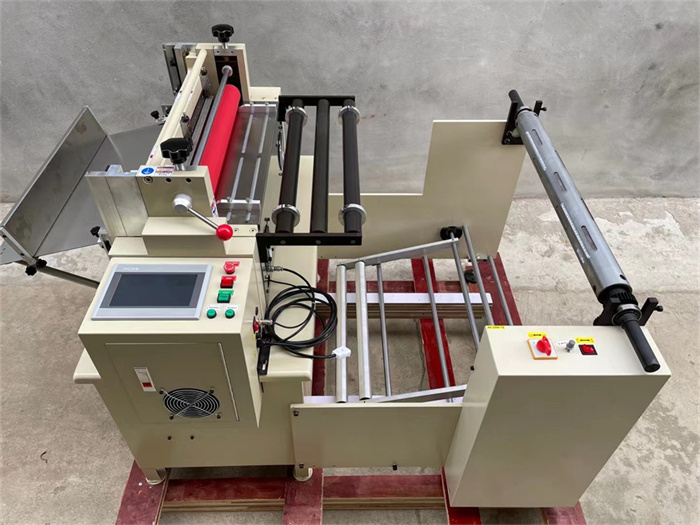

Automatic Good Quality Polyester Film Cutting Machine

Function of machine

Sheet cutting for all kinds of paper, aluminum foil, copper foil, PET, PC, PVC, PCB, FPC, Lithium battery film, flannelette and all kinds of non-metal material in roll form. Pls see below sketch.

Technical Parameter

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Features of machine

1. We are specialized in roll to sheet cutting machine. We are the real manufacturer, not trading company.

2. We use the latest Mitsubishi PLC control in machine.

3. We use Taiwan's newest WEINVIEW touch screen.

4. We use the latest servo motor control. We use 2 servo motors for the cutter and feeder. Precision is within 0.03mm.

5. We use a 40mm thick cast iron body, which will not be deformed for more than ten years and has higher accuracy. You must know CNC processing machines are all cast iron bodies, which will not be deformed for a long time.

6. Our machine structure is stable. For unwinder, it is connected with machine that can stand 300kg roll weight. It is automatic unwinding by motor.

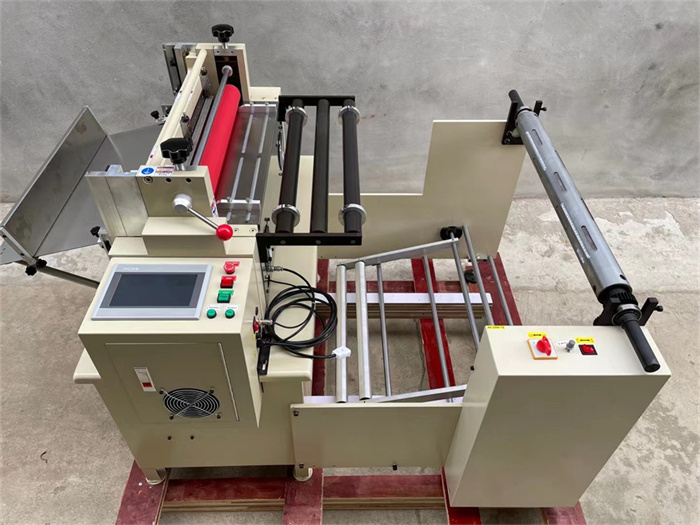

Machine configuration

1. Cutting Blade

Material : SKD-11Lifetime : About 1 Billion times cuts. Scissor-type cutting blade, durable with highest hardness 65 HRC .Easy to adjust, sharp ,maintain,and change.Warranty: This is spare part , due to consumable parts.

2. Touch Screen

You Can Set All Parameter In Touch Screen, The Length, Batch Quantity, Total Quantity, Cutting Speed Etc. It's Convenient For Workers To Operate The Machine.

3. 2 sets Servo Motors

This machine is equipped with 2 pcs Servo motors control. They are cooperated with feeding roller, make sure the cutting precision and feeding precision could reach 0.03 mm.

4. Automatic Unwinding Device

Material Unwinding Stand For Automatic Roll To Sheet Cutter, It Supports Max 300kg Material Roll.

Optional Parts

1. Photo sensor. If your materials are printed, you need to add it.

2. Conveyor belt. If your material is thin and soft, you need to add it,

Advantages of Polyester Film Cutting Machine

Polyester film cutting machines are an essential tool for industries and businesses dealing with thin films. These machines are specially designed to provide accurate, efficient, and consistent sheet cutting of thin film materials with minimal waste. In this blog, we will discuss some of the advantages of Polyester film cutting machine.

1. High Precision Cutting

Polyester film cutting machine use advanced cutting technologies such as cutting blade to provide precise cutting of thin films.

2. Consistent Quality

Polyester film cutting machine provide consistent quality and repeatability in the cutting process. They can slice multiple layers of films at the same time, ensuring that every cut is uniform and meets the required specifications.

3. Increased Efficiency

Polyester film cutting machine significantly increase production efficiency. They can process large rolls of film in a short time, resulting in faster turnaround times and reduced labor costs. Additionally, automated feeding and cutting systems minimize operator intervention and reduce the chances of errors.

4. Reduced Waste

Polyester film cutting machine are designed to reduce waste by optimizing the use of materials. They can cut films with minimal kerf, resulting in higher yield and reduced waste. Furthermore, automated scrap removal systems ensure that waste is quickly and efficiently removed from the cutting area.

5. Easy to Use

Polyester film cutting machine are user-friendly and intuitive to operate. They come with touch screen interfaces and software that allows for easy set-up and control of the cutting parameters. Additionally, they require minimal maintenance, which reduces operational downtime and ensures maximum uptime.

In conclusion, Polyester film cutting machine provide accurate, efficient, and consistent sheet cutting of thin film materials, resulting in significant cost savings and improved production quality. Investing in a high-quality Polyester film cutting machine is an excellent decision for businesses and industries that require precise and efficient cutting of thin films.

FAQ

Q: What is the lead time of your sheet cutting machine?

A: Our production cycle is relatively short, usually within 20-30 days. We can also do expedited production according to customer demand.

Q: Does your sheet cutting machine have after-sales service?

A: Yes, we provide perfect after-sales service, including remote technical support, door-to-door service and so on. Our service team also visits customers regularly to ensure customer satisfaction.

Q: What is the failure rate of the machine?

A: Our machine has been tested and improved many times, and the failure rate is very low. We also provide preventive maintenance services to ensure that machines are kept in good running condition.

Q: How to ensure the durability and reliability of the machine?

A: High quality steel and castings are selected to ensure that the machine is strong and durable. Perform strict machine performance test and quality inspection to ensure machine reliability. Provide professional maintenance services, prolong the life of the machine.