Application Of Roll To Sheet Cutting Machine

To cut materials from rolls to sheets, as below structure. Set cutting length and cutting quantity in touch screen as you need.

Automatic roll to sheet cutting machine can cut many different kinds of materials, like paper, printed material, conductive fabric, foam, diffuser, reflector film, double-sided adhesive tape, nickel plate, PET, PC, PE insulation paper, copper /aluminum foil and all kinds of adhesive tapes. Pls see reference as below.

Features of automatic roll to sheet cutting machine

1. The max width: 360, 500, 600, 700, 1000, customized

2. Cutting Precision: 0.03mm

3. Material thickness: 0.5mm-20mm (according to different materials)

4. Cutting speed: 0-100 cut/min

5. Both kiss-cut and complete cut are available; Complete cut is for standard machine, and kiss-cut is an option

6. A conbination of PLC and servo motor

7. Eye mark device for optional

8. An air shaft as the loading shaft

9. Two accessories, static eliminator and conveyor belt, for you to choose 10. Automatic unwinding function

11. Operation is easy

12. Waste rate is low

Parameters of automatic roll to sheet cutting machine

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Features of automatic roll to sheet cutting machine

BOPP film cutting machine is an efficient, precise and automatic cutting equipment. BOPP film is a kind of polypropylene film, which is widely used in packaging materials in food, medicine, cosmetics, clothing, stationery and other industries. The features and advantages of BOPP film cutting machine mainly include the following aspects.

1. Efficient and precise: BOPP film cutting machine adopts high-precision PLC control system and frequency conversion speed regulation technology, which can achieve high-precision automatic cutting. At the same time, by optimizing the design and improving the slicing technology, the cutting speed and efficiency have been significantly improved, and the production efficiency has been greatly improved.

2. Safe and reliable: BOPP film cutting machine adopts multiple safety protection measures to ensure the safety of operators. In the design and manufacturing process of the equipment, high-quality components and raw materials are used, which makes the service life of the machine more long and stable.

3. Intelligent automation: The whole cutting process of BOPP film cutting machine can realize unmanned operation throughout the whole process, and only some simple settings and monitoring are required by personnel on the operation console. At the same time, through the intelligent metering and counting device, the automatic control and monitoring of the cutting length and quantity are realized.

4. Good adaptability: BOPP film cutting machine has high adaptability and flexibility, which can meet the cutting needs of different sizes, thicknesses and materials. By adjusting the cutting parameters and changing the tools, it is possible to automate the cutting of different scenarios.

The features and advantages of BOPP film cutting machine make it an indispensable part of the modern packaging industry. With the development of the packaging industry and the continuous improvement of demand, BOPP film coil slicer will become more and more popular and become an important part of production process automation.

Machine photos

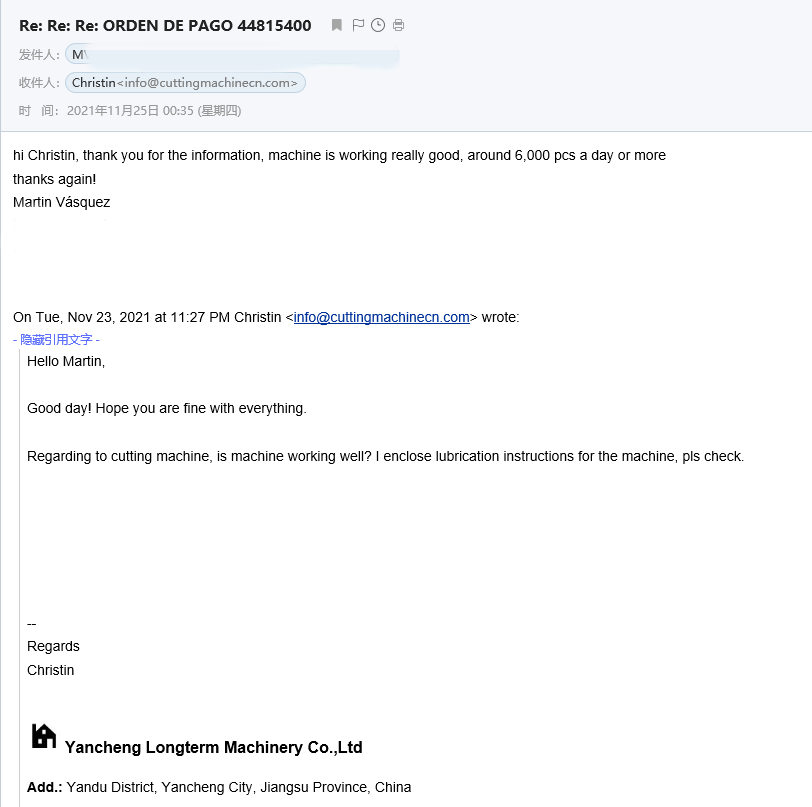

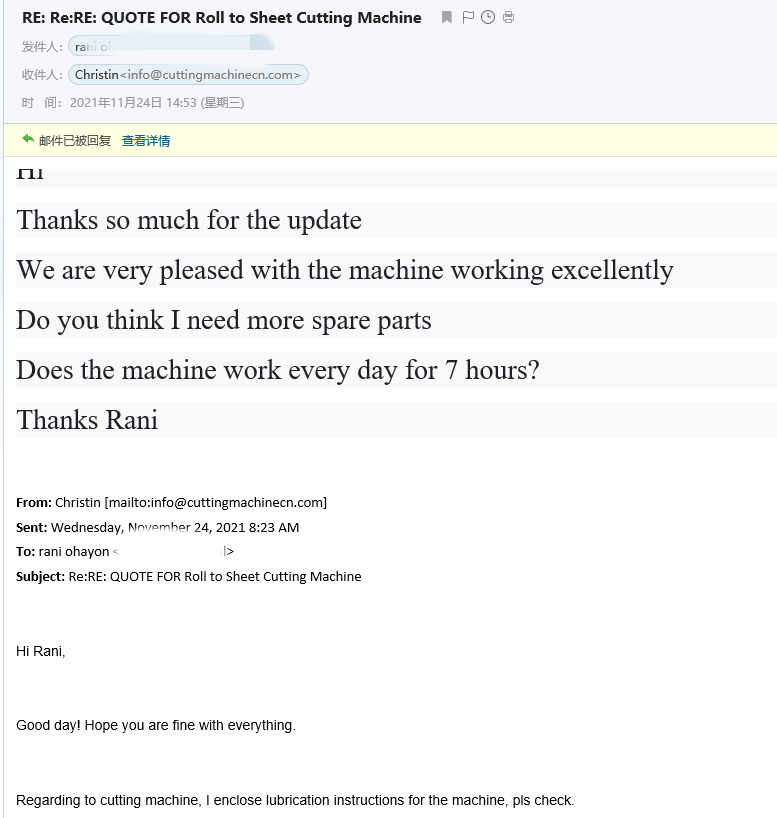

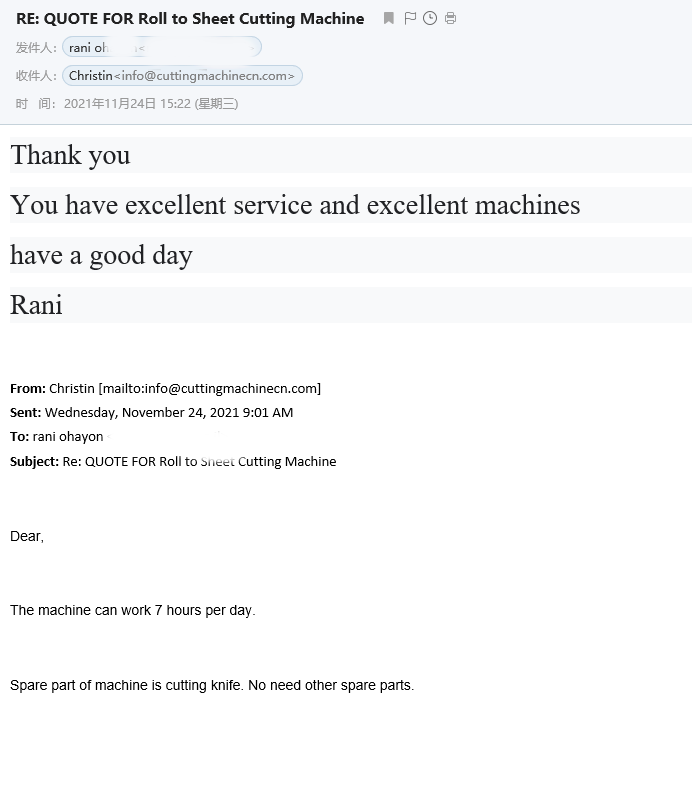

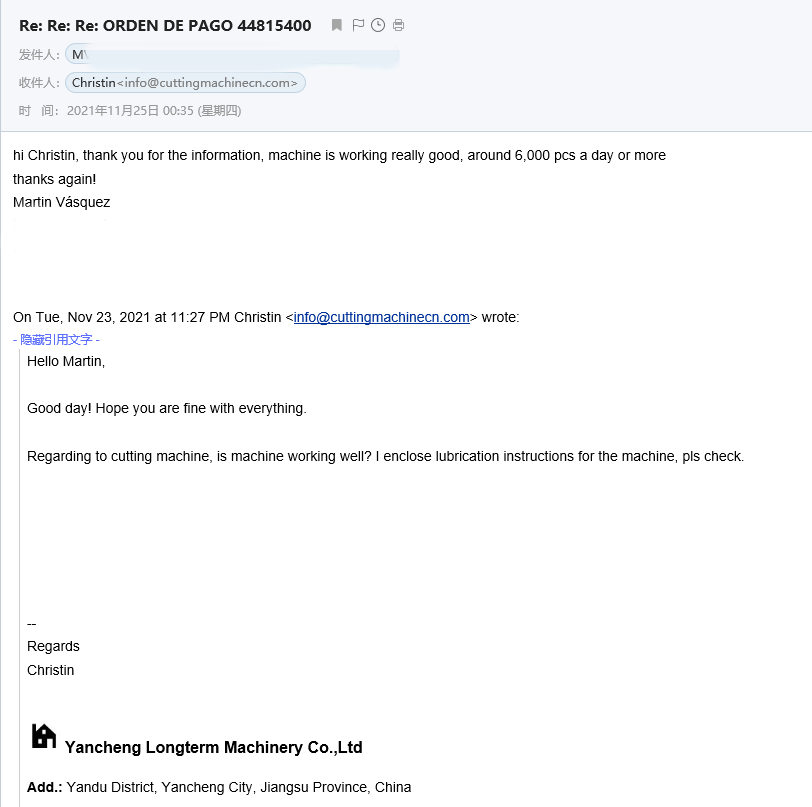

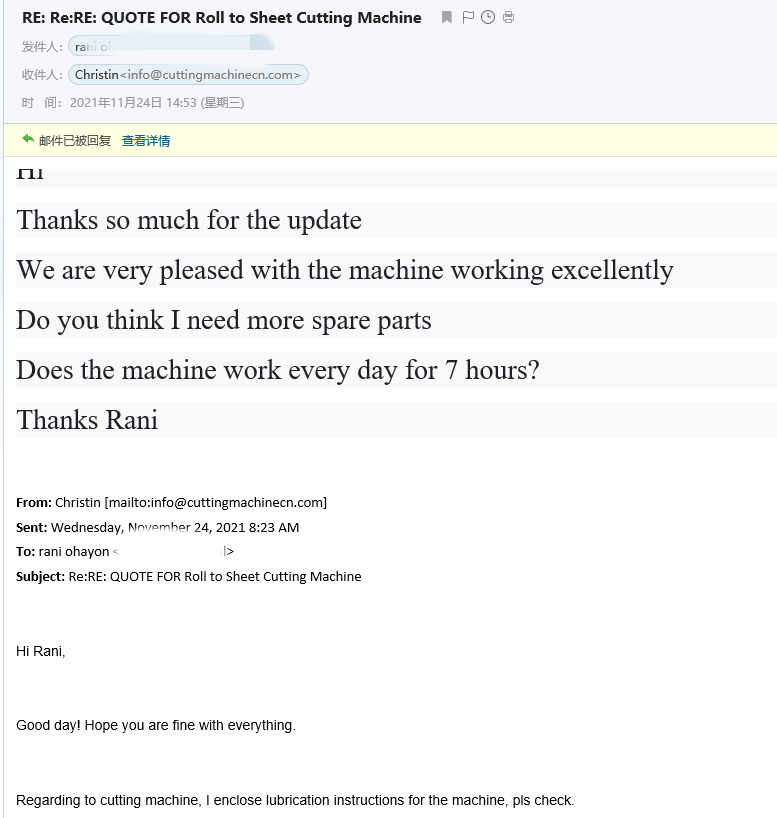

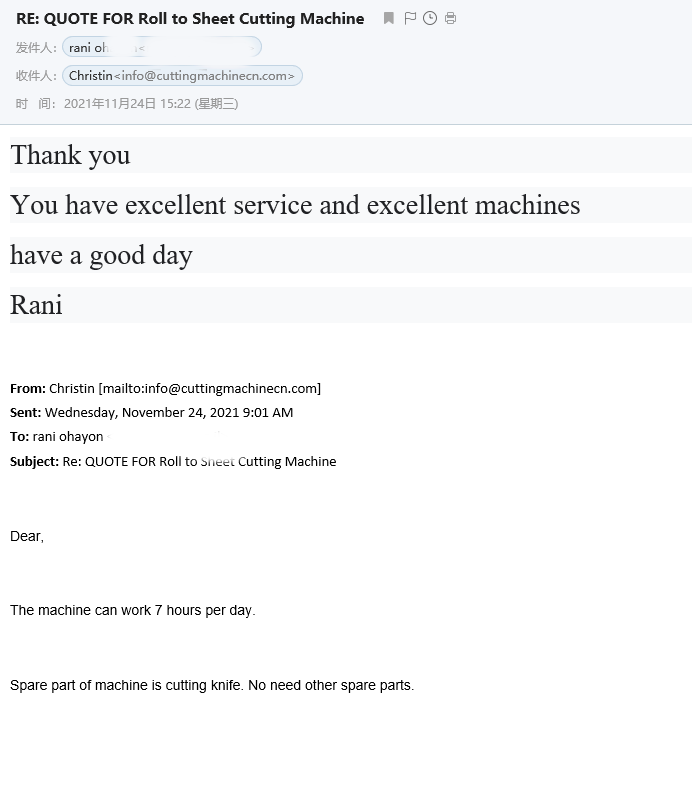

We have good comments from customers for the roll to sheet cutting machine

After-service

1. Warranty for machines is 12 months

2. A promptly reply within 24 hours

3. Free usage training before delivering machines in factory

Q1: Are you manufacturer or trading company?

A: We have our own factory and export team, welcome to visit our factory, we can pick you up at the airport

Q2:: Do you have relevant certificate?

A: Yes, so far, we have CE. we also can issue CO, Form E, etc if you need.

Q3: Do you inspect the finished machines?

A: Yes, we have QC department, they will inspect every machine before packing and provide test video to ensure there is nothing problem of the machines.

Q4: What payment terms are accepted?

A: TT (Telegraphic Transfer), LC, etc.

Q5 : When can the machine be shipped after order is placed?

A It depends on machine model and quantity, some stock machines can be shipped within 3 working days after payment, other customized machines start production after deposit arrived, please contact our staff for detail info.

Q6: How about the warranty and after-sale service?

A: Our machines have two years warranty and lifetime technical support. Help is always just one call or email, and then we can provide a suitable solution within 8 hours after analyzing and estimating the problem. Remote training and door-to-door service is available