Automatic Glass-fiber Slitting Rewinding Machine

Slitting machine technical parameters

| Model | LT-1300F |

| Max. unwind mother roll diameter | 600mm |

| Max. unwind mother roll width | 1300mm |

| Paper inner diameter | 76mm |

| Slitting width | 20-1300mm |

| Machine speed | 160m/min |

| Slitting speed | 150m/min |

| Max rewind diameter | 500mm×2 rolls |

| Rewind shaft diameter | 1" ,2" ,3"(standard 3", 2pcs install) |

| Slitting precision | ±0.5mm |

| Voltage | customized |

| Total power | 5.5-10KW |

| Gross Weight | 1000-2500kg |

| Overall dimension | 2.6×1.7×1.5m |

Slitting machine features

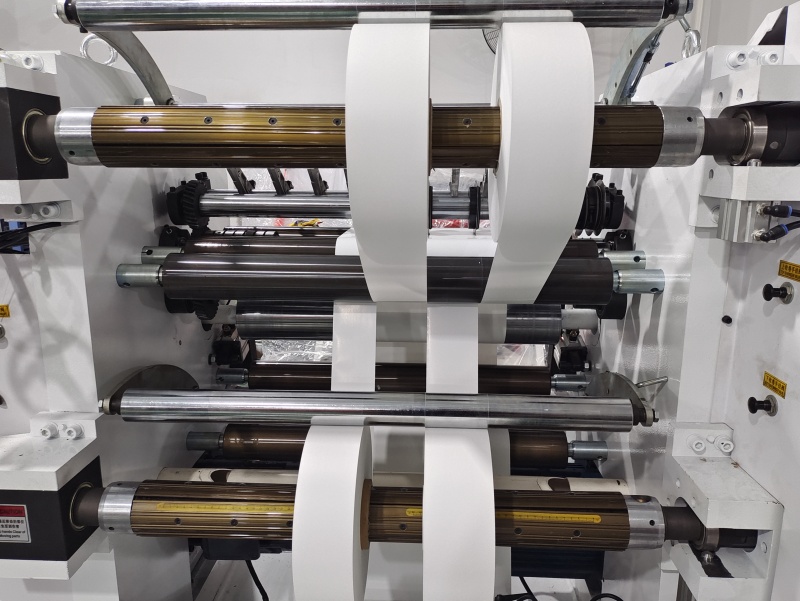

1. Motor equipped with inverter for speed regulation.

2. Separated General Control Cabinet, more convenient operation.

3. Automatic EPC for unwinding, photocell is suitable for tracking edges.

4. Equipped with air shaft for unwinding, material loading magnetic powder brake and automatic tension controller.

5. Air shaft for rewinding. Magnetic powder clutch for rewinding tension controller.

6. Equipped with air trim discharge conveying system .

7. Automatic meter counting device .

8. Pressure roller for rewinding to make rewinding roll moreuniform

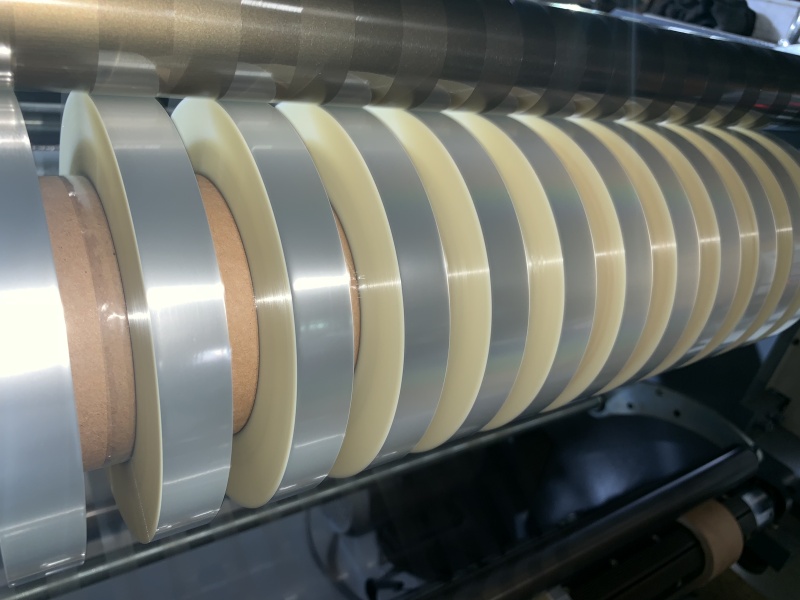

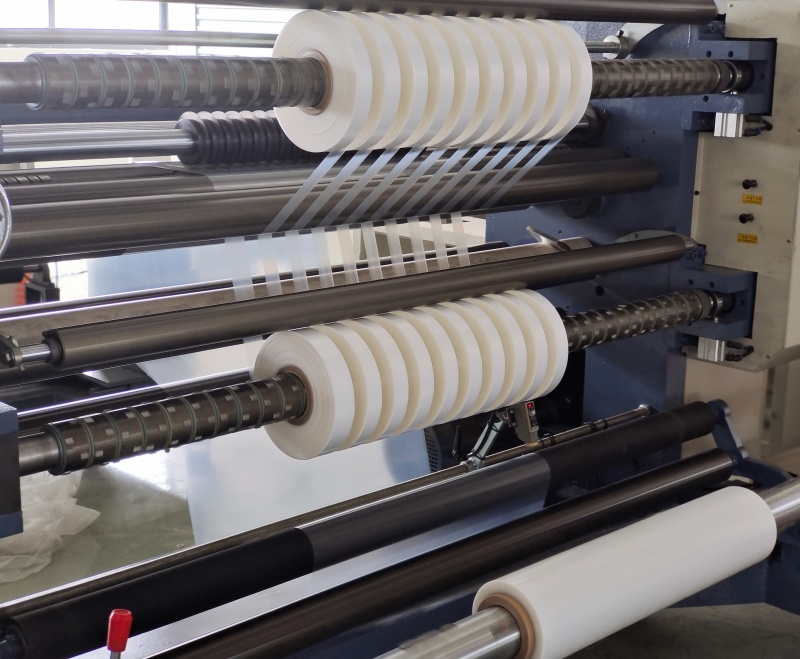

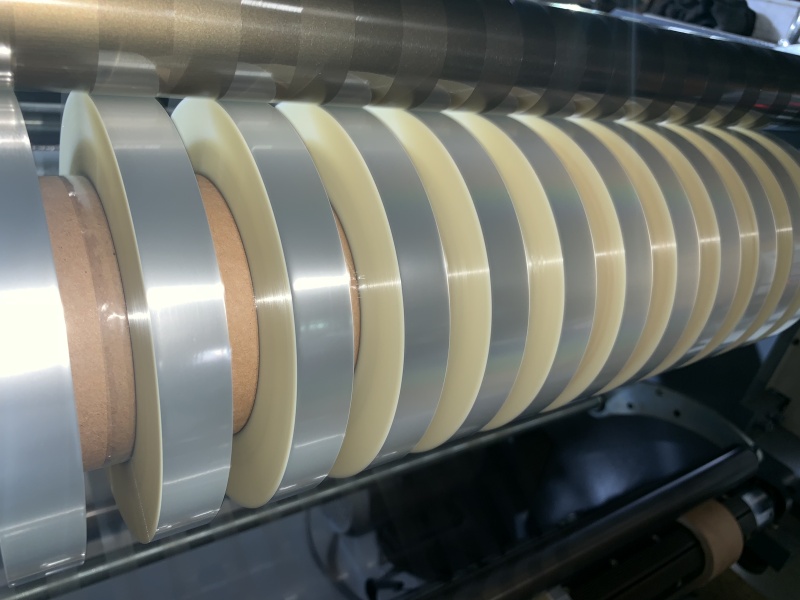

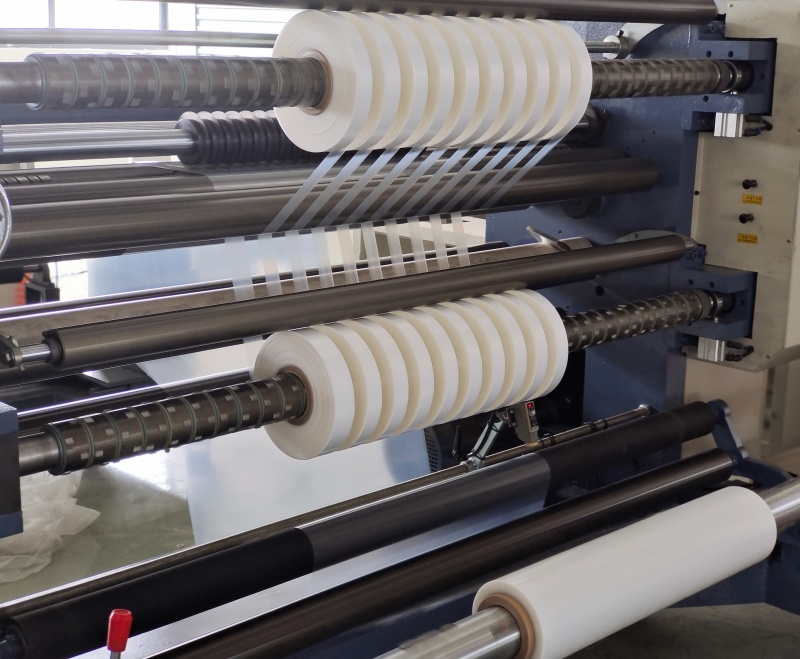

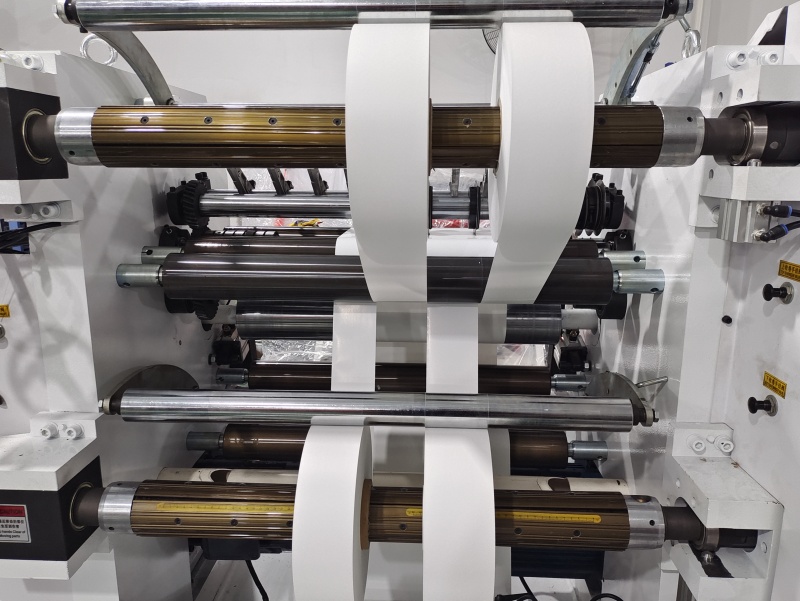

Based on good quality of slitting machine, the effect is pretty good. Pls see below photos.

There are options of slitting blades and rewinding shafts.

For slitting blades:

1. Round slitting blades

2. Straight slitting blade

For rewinding shafts

1. standard air shaft

2. Slide spindle

Glass Fiber Slitting Rewinding Machine: Benefits and Advantages

As the world continues to advance technologically, the demand for high-quality materials has increased. One such material that has become increasingly important is glass fiber. This is because glass fiber is strong, lightweight, and has excellent electrical and thermal insulation properties. To meet the growing demand for glass fiber, manufacturing companies are increasingly turning to glass fiber slitting rewinding machines. These machines provide a cost-effective and efficient way of processing glass fiber into various sizes and shapes. In this article, we will explore the benefits and advantages of glass fiber slitting rewinding machines.

1. High Efficiency

Glass fiber slitting rewinding machines are designed to operate at high speeds, making them highly efficient. This means that they can process a large volume of glass fiber in a short amount of time. As a result, manufacturing companies can significantly increase their production capacity and reduce their manufacturing lead times.

2. Accurate Cutting

The cutting accuracy of glass fiber slitting rewinding machines is unmatched. The machines use advanced tools and cutting systems to ensure that every cut is precise and accurate. This results in high-quality glass fiber products that meet the exact specifications required by manufacturers.

3. High-Quality Rewinding

Glass fiber slitting rewinding machines are designed to produce high-quality rewinding of the processed materials. This means that the machine can rewind glass fiber rolls of different widths and thicknesses with precise tension control. The result is a flawless and even winding of the glass fiber product, ensuring that it is ready for transportation and use.

4. Versatility

Glass fiber slitting rewinding machines are designed to process various forms of glass fiber. They can handle different thicknesses, widths, and lengths of glass fiber and can produce different sizes and shapes of glass fiber products. This makes them highly versatile and suitable for use in different manufacturing processes.

5. Reduced Material Waste

One of the main benefits of glass fiber slitting rewinding machines is that they significantly reduce material waste. The machines are designed to use cutting and rewinding systems that minimize the amount of material waste produced during the production process. This means that manufacturing companies can save on material costs and reduce their impact on the environment.

Conclusion

Glass fiber slitting rewinding machines have become an essential part of the glass fiber manufacturing industry. They provide a cost-effective, efficient, and accurate way of processing glass fiber into various sizes and shapes. The benefits and advantages of these machines are numerous, including increased production capacity, accurate cutting, high-quality rewinding, versatility, and reduced material waste. As manufacturing companies continue to seek ways to improve their processes and reduce costs, glass fiber slitting rewinding machines will continue to play an important role in the industry.