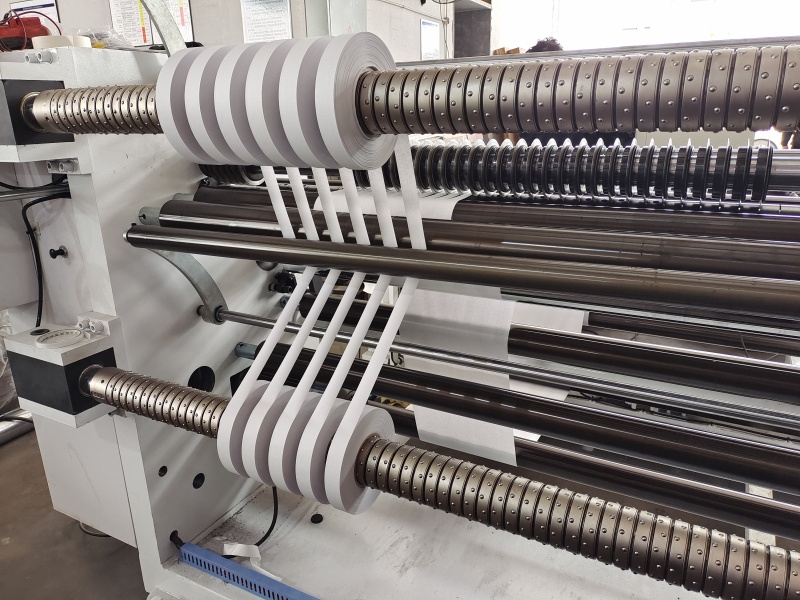

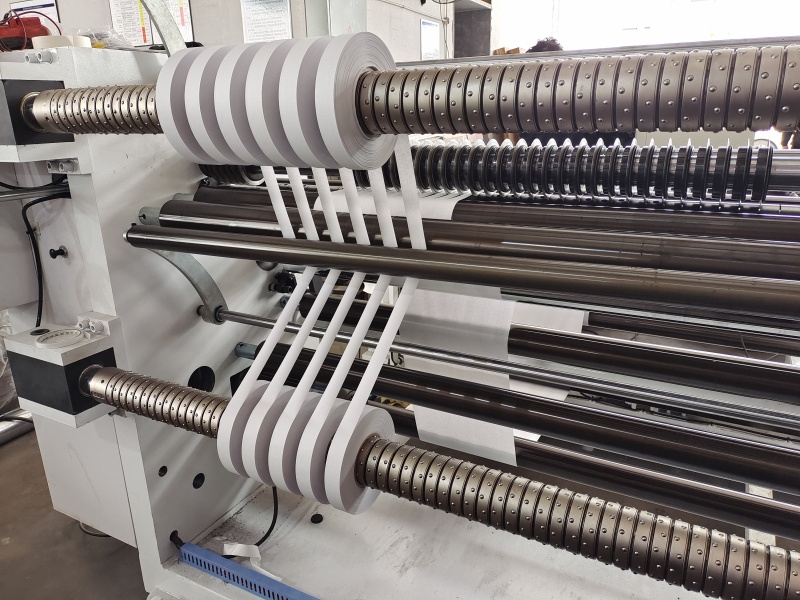

Jumbo Nonwoven Roll Automatic Slitting Rewinding Machine

Application

Suitable Material: Our company's' slitting machines are suitable for slitting various printing and packaging paper, composite aluminum plastic film, polypropylene, polyethylene film composite, BOPP, PET, PE, PVC, pearl film and other materials.

Basic machine details

| 1 | SLITTING WIDTH | 300mm-1600MM |

| 2 | SLITTING THICKNESS | 12-250UM 40-250gram |

| 3 | UNWIND DIA. | MAX1300MM |

| 4 | UNWIND CORE I.D. | SHAFTLESS 3 INCH AND 6 INCH |

| 5 | REWINDING DIA. | MAX 600MM |

| 6 | REWINDING WIDTH | MINI 30MM |

| 7 | REWINDING CORE I.D | 3 INCH SLIPPING AIR SHAFT |

| 8 | SLITTING UNIT | RAZOR BLADE EACH 10 PCS |

|

| SHEAR CIRCLE BLADE 10 PCS |

| 9 | MECHANICAL SPEED | MAX550M/MIN |

| 10 | WORKING SPEED | MAX500M/MIN |

| 11 | MACHINE FRAME THICKNESS: | 50MM |

| 12 | METER COUNTER: | METER COUNTER |

| 13 | WASTE EDGE UNIT: | AIR BLOWER |

| 14 | POWER SOURCE | 380V,3 PHASE 4 WIRES,50Hz |

| 15 | PNEUMATIC SOURCE | 0.8MPA |

| 16 | LASER POSITIONING | 10 PCS |

| 17 | WITH AUTO UNLOADING FUNCTION FOR FINISHED ROLL |

| 18 | MACHINE SIZE (REF. ONLY): | 2950mm(not including unloading frame tree)×2550mm×1970mm |

| 19 |

| 4590mm(including the unloading frame tree)×2550mm×1970mm |

| 20 | FLOOR SPACE(REF.ONLY): | 4200MM*3300MM |

| 21 | N.W/G.W (REF. ONLY): | 3000/3500 |

Rewinding and Slitting effect

1 3 INCH NORMAL AIR SHAFT to ensure the rewinding tension stable;

2 Full width pressing rollers by air control to ensure the finished roll surface keep smooth;

3 Anti Stati Remove Brush for both up and down rewinding press roller

4 Small indiviual press roller specially designed for the individual roll which not average thickness

5 Manual laser core position units help to set paper/plastic cores easily and quickly, begin next slit run with very short downtime.

6 Automatic tension control to ensure the rewinding tension stable.

Unwinding

1 Magnetic Brake with load cell close loop system for unwind tension control;

2 3 inch and 6 inch shaftless uwinding system, easily change the jumbo roll;

3 Hydraulic lifting system to help the operator loading the jumbo roll max. 1 ton from floor;

4 Material splice table, easy change and guarantee edge consistency ;

5 EPC ultrasonic edge guider to avoid the influnce from shinning materia which reflect light back;

6 Back Control Button & Screen Display make the operator easily control the slitter at back side;

3 SECURITY GRAVITY CARPET to ensure the safty of the operator;