Paper Sheeter Machine: The Functionality

A paper sheeter machine is a device that is used to cut paper rolls into sheets. It is an important tool in the printing industry, stationery manufacturing. If you are thinking of buying a paper sheeter machine or want to know more about its functionality, then read on! In this blog, we will discuss in detail the functions of a paper sheeter machine.

The primary function of a paper sheeter machine is to cut large rolls of paper into smaller sizes. The machine is equipped with a sharp blade or blade system to make the cut. The size of the blade and the power of the machine determine the thickness of the paper that can be cut.

The second function of the machine is accuracy. With a paper sheeter machine, you can achieve high levels of precision when cutting your paper, ensuring that your paper sheets meet the required size. This precision makes it ideal for cutting materials such as business cards, postcards, and invitations.

Another function of a paper sheeter machine is speed. Manual cutting with a pair of scissors or a paper cutter can be tedious and time-consuming. However, with a paper cutting machine, you can cut multiple sheets of paper in a matter of seconds. This makes it ideal for handling large printing or office tasks.

Lastly, paper sheeter machines come with safety features to ensure the safety of the user. The blade system is enclosed, and the machine is equipped with safety guards to prevent accidental injuries.

In conclusion, a paper sheeter machine is an essential tool for individuals and businesses that handle large amounts of paper or require precision and speed when cutting paper sheets. It plays a crucial role in the printing, stationery manufacturing, and office setups, making it an invaluable asset for any business that uses paper.

Application

Function of sheeter cutting machine is to cut materials from rolls to sheets as below image. Set cutting length and cutting quantity in touch screen as you need.

Machine can cut all kind paper, aluminum foil, copper foil, PET, PC, PVC, PCB, FPC, Lithium battery film, flannelette and all kinds of non-metal materials in roll form.

Machine Features

1.The max width: 360, 500, 600, 700, 1000, customized

2. Precision: 0.03mm

3. Material thickness: 0.5mm-20mm

4. Cutting speed: 100cut/min;

5. Both kiss-cut and complete cut are available;

6. Complete cut is for standard machine, and kiss-cut is an option;

7. A conbination of PLC and servo motor.

8. Eye mark device for optional

9. An air shaft as the loading shaft;

10. Two accessories, static eliminator and conveyor belt, for you to choose

11. Automatic unwinding function;

12. Cutting length is accurate;

13. Operation is easy;

14. Waste rate is low;

15. Diverse functions satisfy your various requirements;

16. We offer superior-quality products and best service for you;

17. As a high-tech manufacturer, we possess veteran engineers and professional sales team;

Machine configuration

1. Cutting Blade

Material : SKD-11. Lifetime : About 1 Million times cuts. Scissor-type cutting blade, durable with highest hardness 65 HRC. Easy to adjust, sharp, maintain and change. Warranty: This is spare part, due to consumable parts. Normally we will recommend customers to buy one set extra blade as spare parts.

2. Touch Screen

You Can Set All Parameter In Touch Screen, The Length, Batch Quantity, Total Quantity, Cutting Speed Etc. Special program is OK.

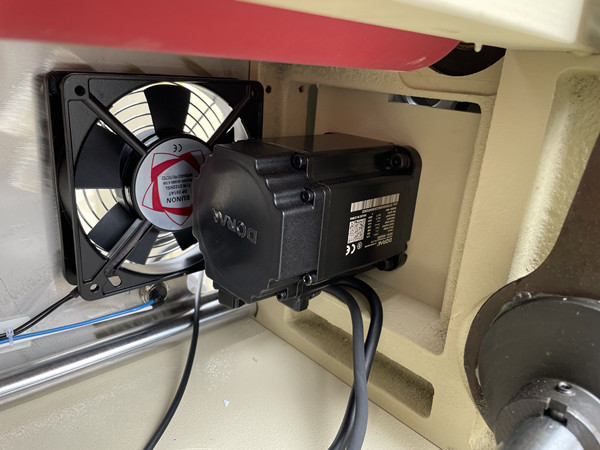

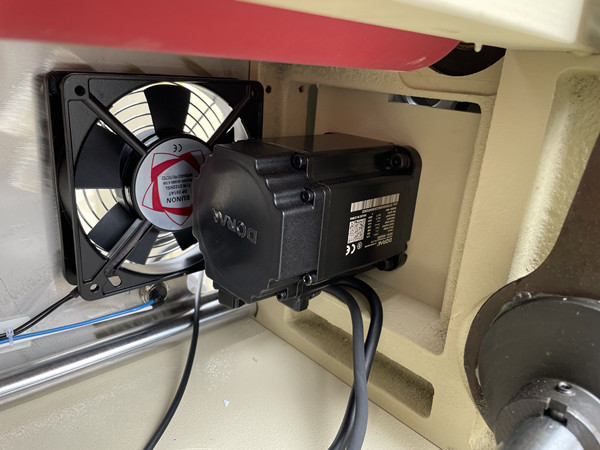

3. 2 Pcs Servo Motors

This machine is equipped with 2 pcs Servo motors control. They are cooperated with feeding roller, make sure the cutting precision and feeding precision could reach 0.03 mm.

4. Automatic Unwinding Device

Material Unwinding Stand For Automatic Roll To Sheet Cutter, It Supports Max 300kg Material Roll.

Optional Part

1. Photo Sensor

If We Add Photo Sensor For Cutting Machine, It Can Cut The Printed Material. The Photo Sensor Will Sense The Printed Marking And Make Sure The Cutting Blade Cut The Right Position.

2.Conveyor Belt

It is for soft materials.

Machine CE certificate

After-service

1. Warranty for machines is 12 months

2. A promptly reply within 24 hours

3. Free usage training before delivering machines in factory

Electric Box