Kiss Cutter - A Revolutionary Half Cutting Machine

Kiss cutter, also known as half cutting machine, is a cutting-edge technology used in the manufacturing industry. It is designed to cut through a variety of materials without severing the backing material. This makes it an ideal tool for making stickers, labels, and other adhesive-backed products.

The kiss cutter has a unique design that makes it more precise and efficient than traditional cutting machines. It uses a small blade that is set at an angle to cut through the material without damaging the backing. The blade is mounted on a pin that is guided with a computer-controlled system, ensuring accurate cutting to the desired shape and size.

One of the main advantages of using a kiss cutter is that it allows for high-speed cutting without the need for additional processing. It can handle a wide range of materials, including paper, vinyl, fabric, and more. This means that manufacturing companies can produce a variety of products with ease, making it a cost-effective solution for small to medium-sized businesses.

Another key feature of a kiss cutter is its user-friendly interface. It is easy to operate and requires minimal training. This means that business owners can increase their productivity without having to invest heavily in staff training or additional equipment.

Furthermore, a kiss cutter is a versatile tool that can be used for a variety of applications. It is not limited to the manufacturing sector and can also be used for creating custom designs and products for personal use. This is especially useful for individuals who enjoy crafting or those who run small businesses.

In conclusion, a kiss cutter is a revolutionary cutting machine that has become an indispensable tool for the manufacturing industry. Its speed, accuracy, and versatility make it an ideal tool for producing a wide range of products. With its user-friendly interface, it is also accessible to small businesses and individuals, making it a valuable investment for anyone looking to increase their productivity and efficiency.

Machine Features

1. Max material width: 360mm/500mm/600mm;

2. Precision: 0.02mm;

3. Material thickness range: 0.5mm-15mm;

4. Kiss-cut or cut-through is available;

5. This machine employs HMI and PLC system;

6. It adopts an imported photoelectric tracing device to position, reducing errors.

7. High accuracy and efficiency;

8. Operation is easy;

Application

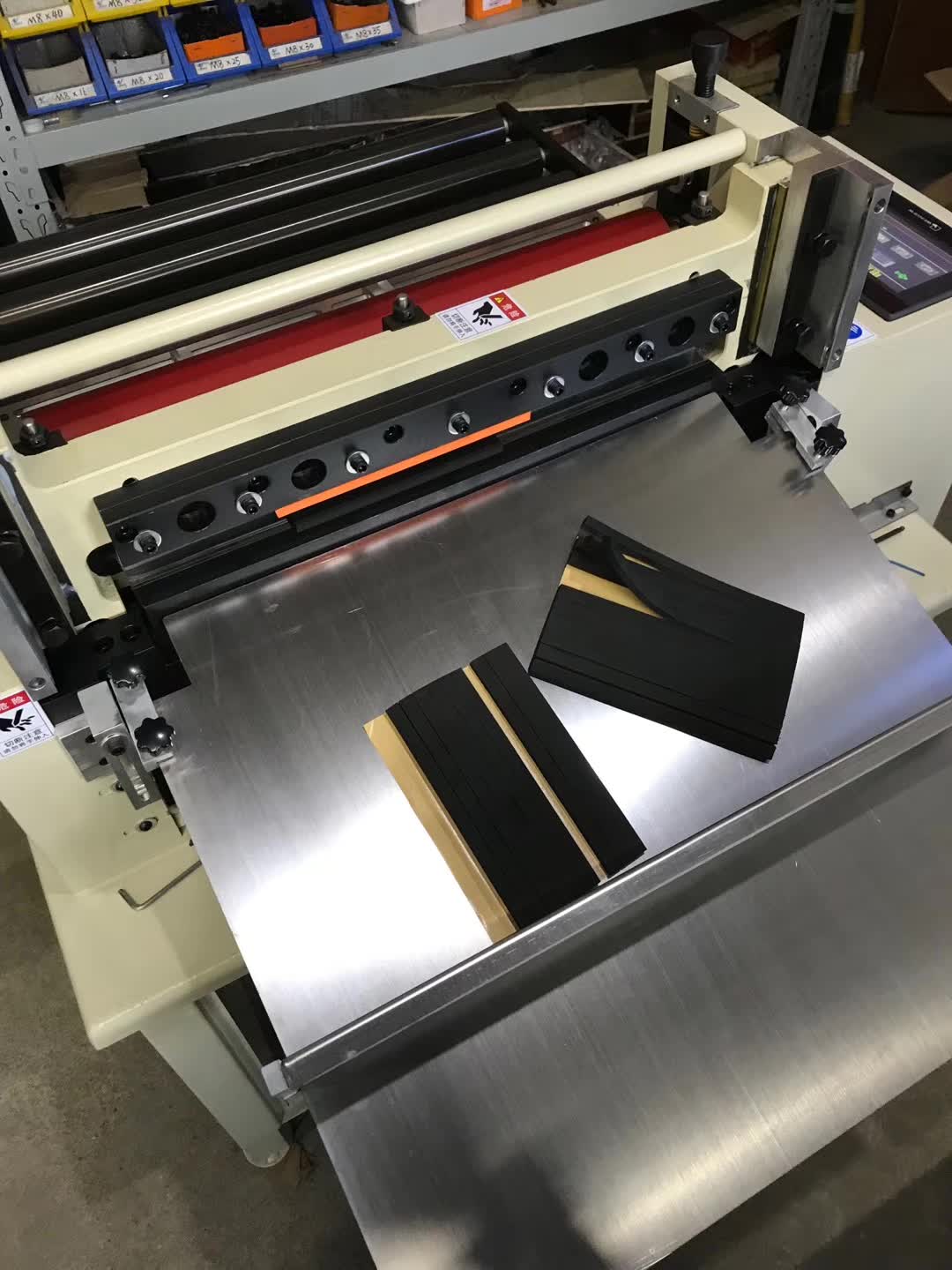

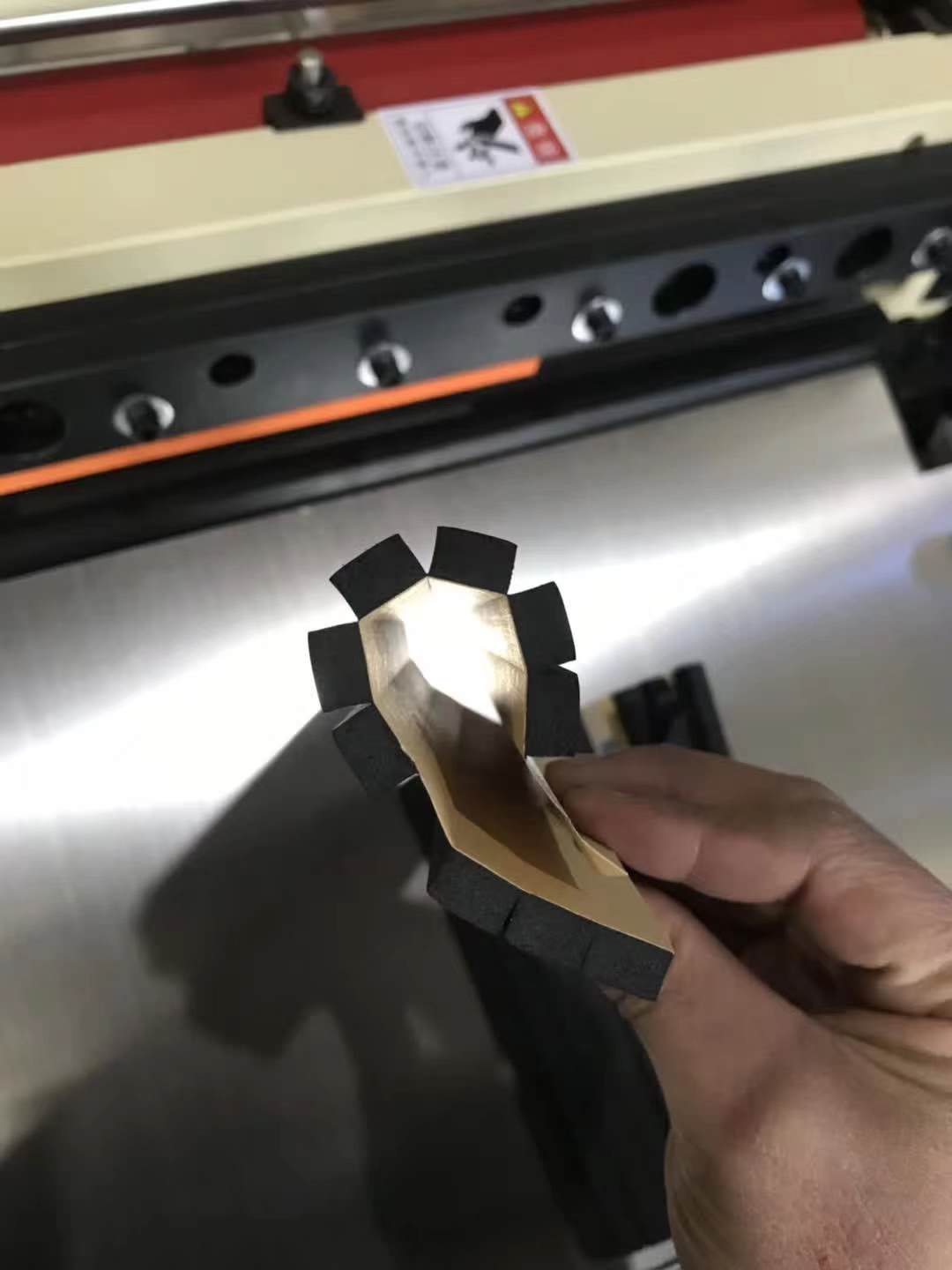

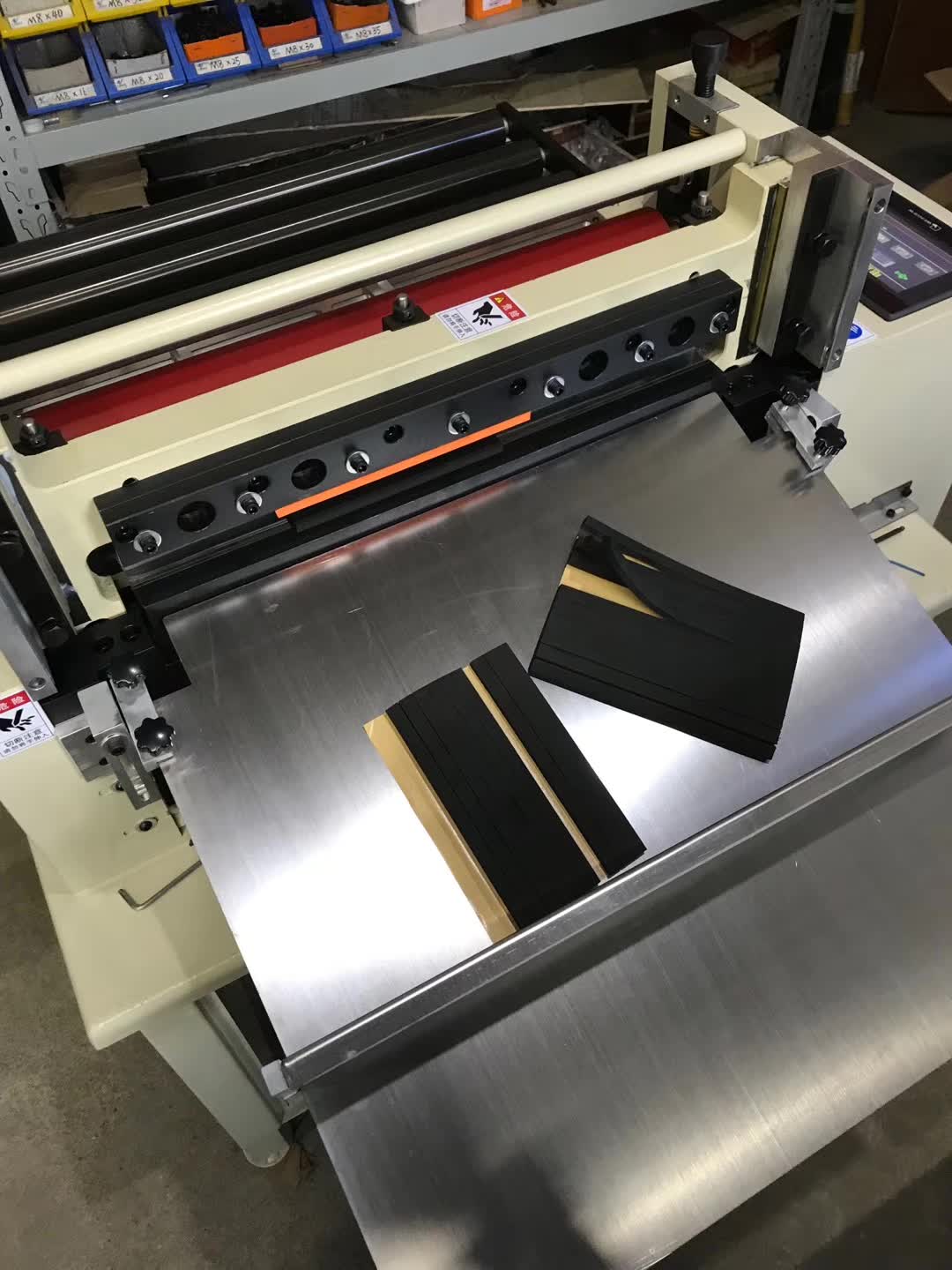

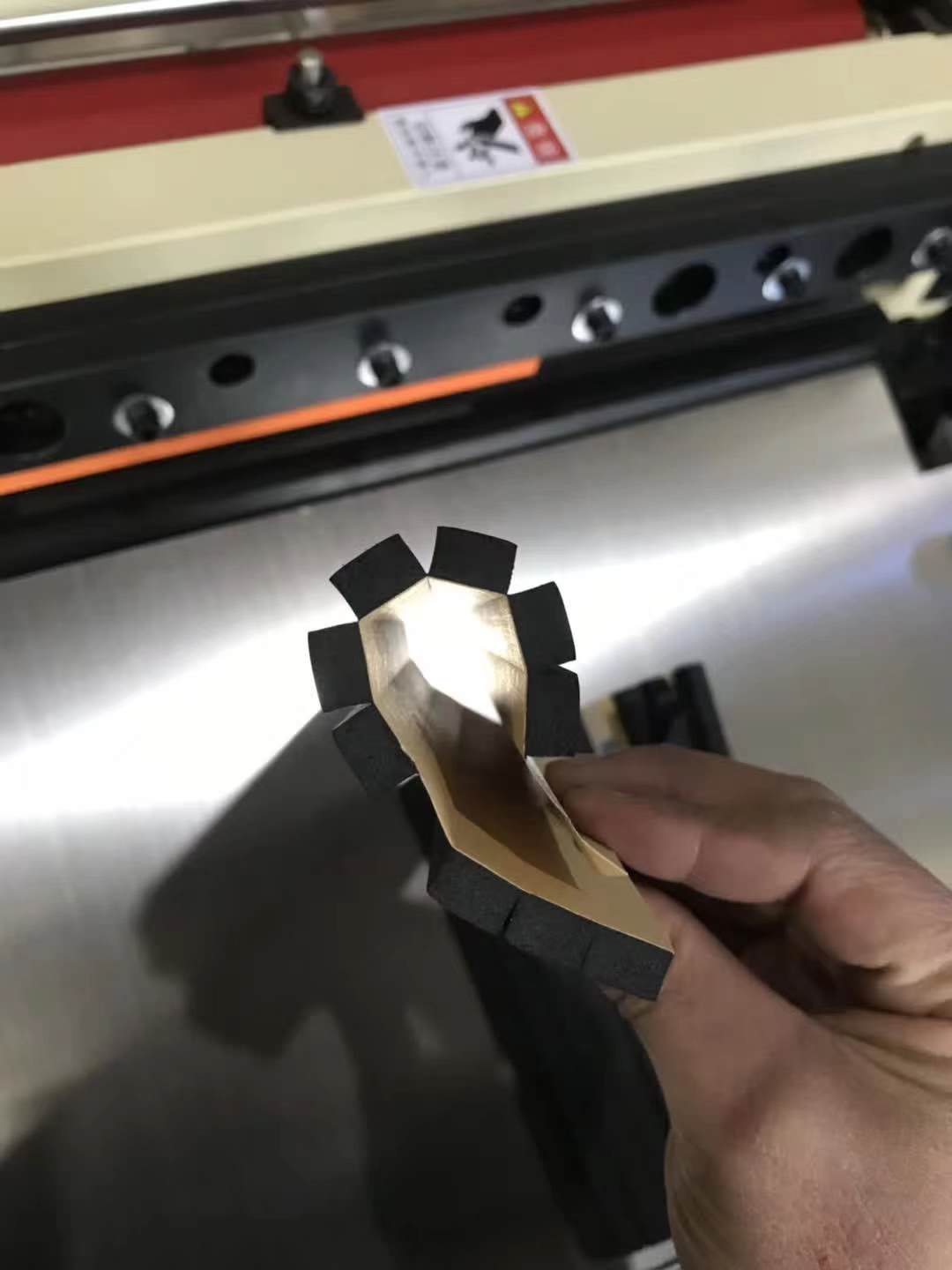

This machine is to cut foam with self-adhesive paper. Foam is cut, but self-adhesive paper is not.

Machine more photos

FAQ

Q: Are you a manufacturer or trading company?

A: We are a professional manufacturer over 10 years' experienee.

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Zhengang Industrial Park, Dagang Town, Yancheng City, Jiangsu Province, China.

You can fly to Shanghai airport directly. We warmly welcome all our dients from home and abroad to visit us!

Q: What are your main products?

A: Our main products are roll to sheet cutting machine, slitting machines, paper tube cutting machine, carton erector machine and carton sealing machine.

Q: How does your factory do regarding quality control?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials, assembly process,

to the finished products. Our factory has obtained CE & ISO Certification.

Q: If there are no suitable machines from your product list, can we customize from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirements.