Features of Roll to Sheet Cutting Machine

1. We are specialized in roll to sheet cutting machine. We are the real manufacturer, not trading company.

2. We use the latest Mitsubishi PLC control in machine.

3. We use Taiwan’s newest WEINVIEW touch screen.

4. We use the latest servo motor control. We use 2 servo motors for the cutter and feeder. Precision is within 0.03mm.

5. We use a 40mm thick cast iron body, which will not be deformed for more than ten years and has higher accuracy. You must know CNC processing machines are all cast iron bodies, which will not be deformed for a long time.

6. Our machine structure is stable. For unwinder, it is connected with machine that can stand 300kg roll weight. It is automatic unwinding by motor.

Application of Roll To Sheet Cutting Machine

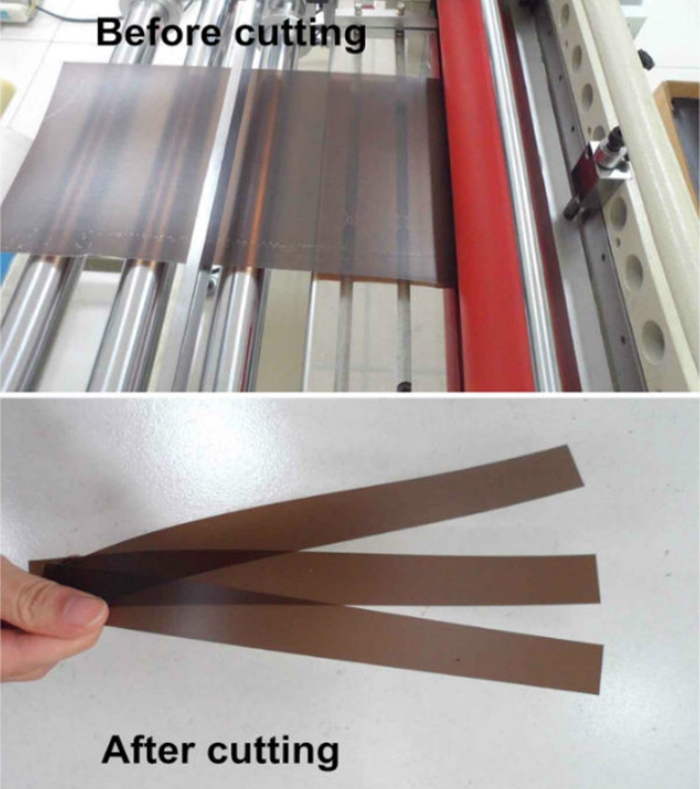

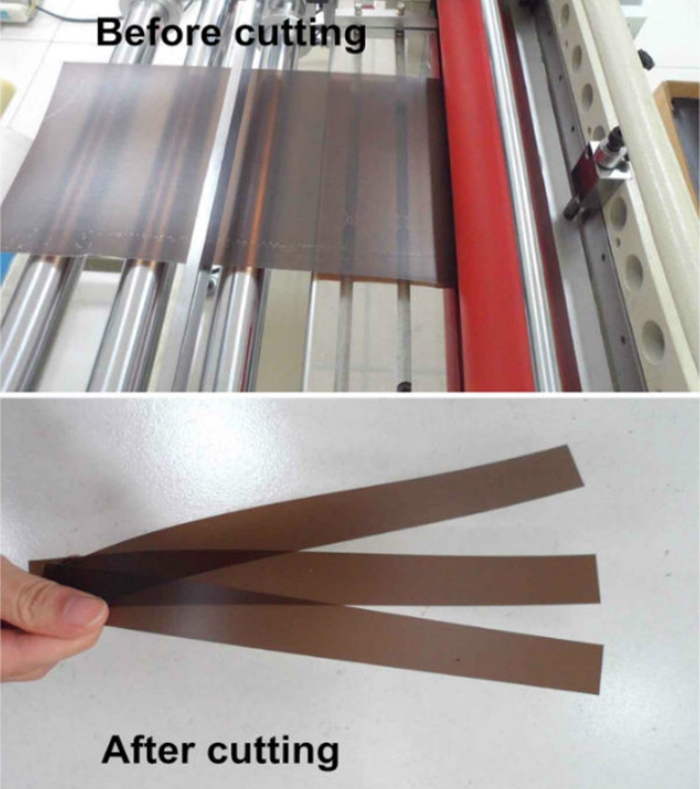

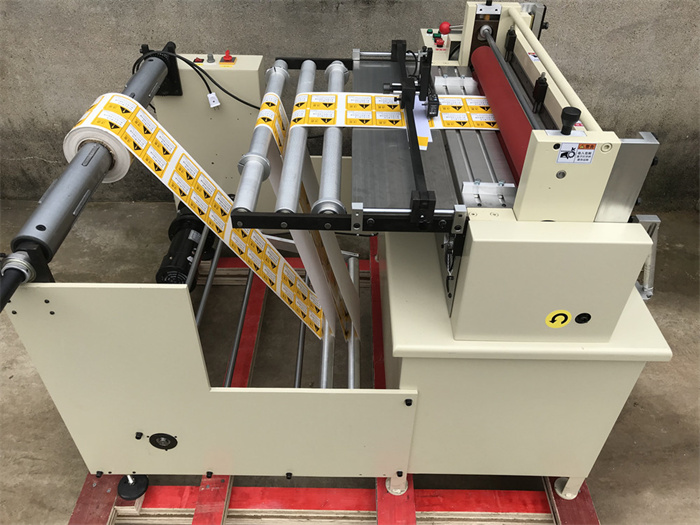

To cut materials from rolls to sheets. Set cutting length and cutting quantity in touch screen as you need. Pls see below photo.

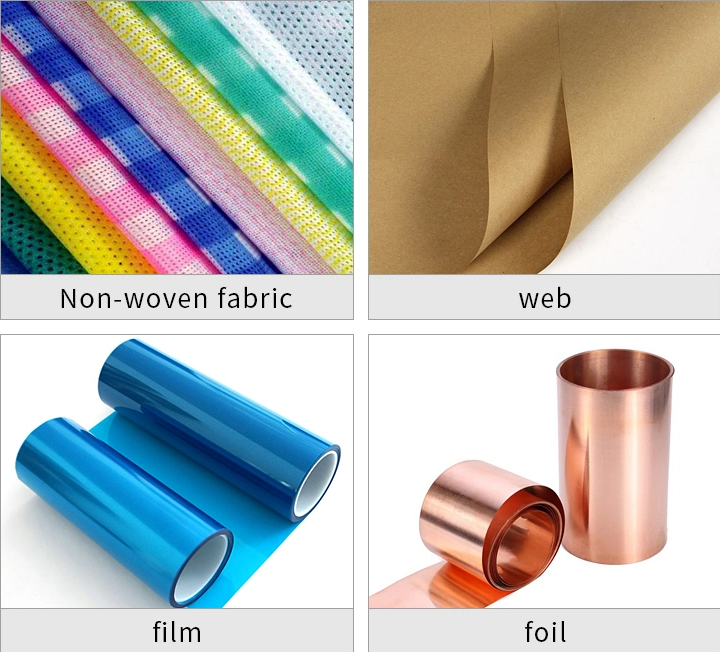

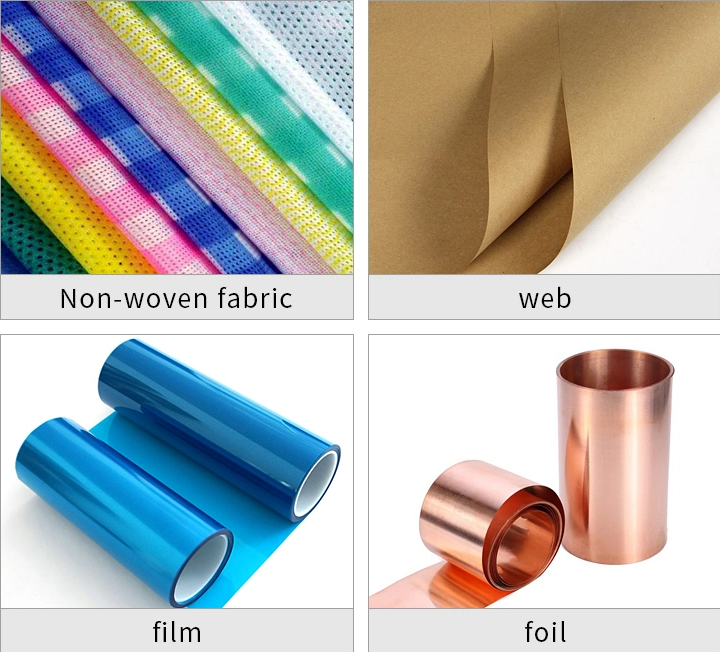

Roll to Sheet cutter can cut many different kinds of materials, as photo below.

Machine Parameters

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Machine configuration

1. Machine uses PLC program control and touch screen operation procedures, Servo motor drives, frequency control.

2. Servo motor control ---more precision then Stepper motor control, so we already eliminated stepper motor machine.

3. PLC ----- use famous brand MITSUBISHI, which you will easily maintenance in your local place.

4. Machine body ----- 252 mm thickness steel wall, it is very solid that to make sure machine stable when running

and the steel wall is whole steel sheet, not connected together .

5. PULLING ROLLER ---- Thick PU rubber coated and won't scratch the material.

6. Guiding roller ------- Aluminum shaft be polished and hard anodized, very smooth and never harm material.

7. Cutting Blade ----SKD11 material to make sure the cutter use very very long time and cutting material perfect edge at cutting part.

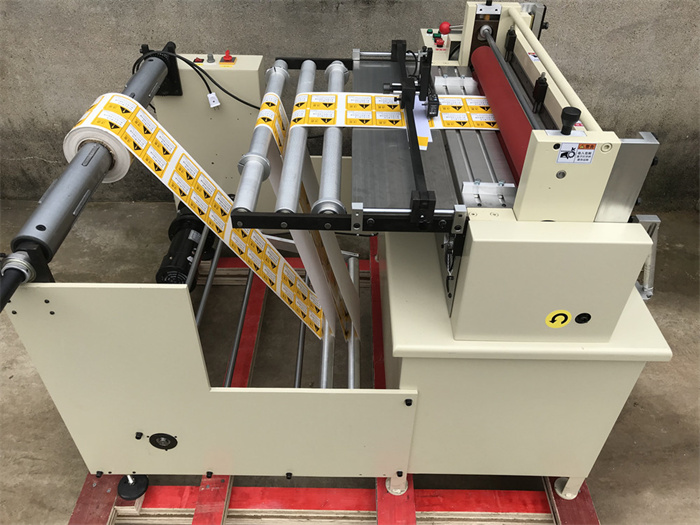

Machine photos

Machine package and shipment

Automatic Label Roll To Sheet Cutting Machine features

Label roll to sheet cutting machine is a versatile equipment used for cutting label rolls into sheets. This machine is widely used in the labeling industry to facilitate higher productivity and efficiency. Here are some of the specific features and advantages of label roll to sheet cutting machine:

1. High Precision: label roll to sheet cutting machines are designed to provide high precision cuts of label rolls. They can cut rolls of varying widths into any size of labels required with accuracy and efficiency. This feature ensures that the labels produced are of high quality and meet the standards set by clients.

2. Easy to Operate: label roll to sheet cutting machines are simple and easy to operate. The equipment is designed with an intuitive interface that allows operators to quickly switch between different settings and parameters. This feature ensures that new operators can be trained quickly and efficiently to operate the machine.

3. Adjustable Speed: label roll to sheet cutting machines come with adjustable speed settings which can cater to different production demands and volumes. The flexibility provided by these adjustment settings ensures that the machine can adapt to the needs of any production floor, regardless of the size or requirements.

4. Low Maintenance: label roll to sheet cutting machines are built to last and require minimal maintenance. The components and parts used in the construction are of high quality which minimizes downtime, and prolongs the lifespan of the machine. This feature ensures that the production process is running smoothly with minimal interruptions.

5. Cost-Effective: label roll to sheet cutting machines offer a cost-effective solution for label production. This equipment provides high-quality cuts, reduces waste, improves efficiency, and allows for rapid production of labels. All these benefits work together to achieve a higher return on investment, making label roll slitting machines an attractive option for cost-conscious businesses.

In conclusion, label roll to sheet cutting machines are efficient and effective equipment for cutting label rolls. Their high-precision cuts, ease of operation, adjustable speeds, low maintenance, and cost-effectiveness are just some of the benefits that make them a valuable addition to the labeling industry.

Company Information

YANCHENG LONGTERM MACHINERY CO., LTD located in YANCHENG city, which with convenient transportation, our company main engaged in roll to sheet cutting machine, die cutting machine, and slitting cutting machine manufacture and sales, our product widely sales to South Asia, West Asia, Africa, Europe, America, etc country and regions market.Our company always insist on the belief of "Faith first, quality first, efficiency first", keep customer's request in our heat, contribute the high quality product and fruitful before sales service, after sales service to customer. YANCHENG LONGTERM MACHINERY COMPANY is willing with domestic and foreign friends hand in hand, create brilliant future, and welcome all over the world customer visit us, calling us and write letter to us

FAQ

1.Are You A Factory Or A Foreign Trade Company?

We are the real factory with more than 10 years experience.

2.If I Know Nothing About Aluminum Foil Cutting Machine, Which Model Should I Choose?

Please tell us your materials, thickness, width then we will provide you professional suggestions.

3. If I Do Not Know How To Operate The Aluminum Foil Cutting Machine, How You Can Help Me?

First, we have detailed user manual and videos for your learning. Second, our engineers will provide you technical support in time. If you want, we can provide you training in our factory or your door.

4.How About The Shipping Cost?

Sea transportation, LCL is OK.

We have a shipping company that has cooperated for many years, which can help you save costs.

5.How About The Price? Can You Make It Cheaper?

The price depends on your needs (function, size, quantity) We will quote you the best discount after receiving your inquiry

6.How About The Payment?

T/T,30% deposit, and balance is after the production is finished and before delivery.

7.What‘s Your Delivery Time?

For our standard model, the delivery time is 10-15 working days. For customzied model, it will need about 20-40 working days.