Application of roll to sheet cutting machine

Function of roll to sheet cutting machine is to cut materials from rolls to sheets as below photo. Machine is with PLC control. Set cutting length and cutting quantity in touch screen as you need.

Machine can cut all kind paper, aluminum foil, copper foil, PET, PC, PVC, PCB, FPC, Lithium battery film, flannelette and all kinds of non-metal materials.

Machine features

1. We are specialized in roll to sheet cutting machine. We are the real manufacturer, not trading company.

2. We use the latest Mitsubishi PLC control in machine.

3. We use Taiwan's newest WEINVIEW touch screen.

4. We use 2 servo motors for the cutter and feeder. Precision is within 0.03mm.

5. We use a 40mm thick cast iron body, which will not be deformed for more than ten years and has higher accuracy. You must know CNC processing machines are all cast iron bodies, which will not be deformed for a long time.

6. Our machine structure is stable. For unwinder, it is connected with machine that can stand 300kg roll weight. It is automatic unwinding by motor.

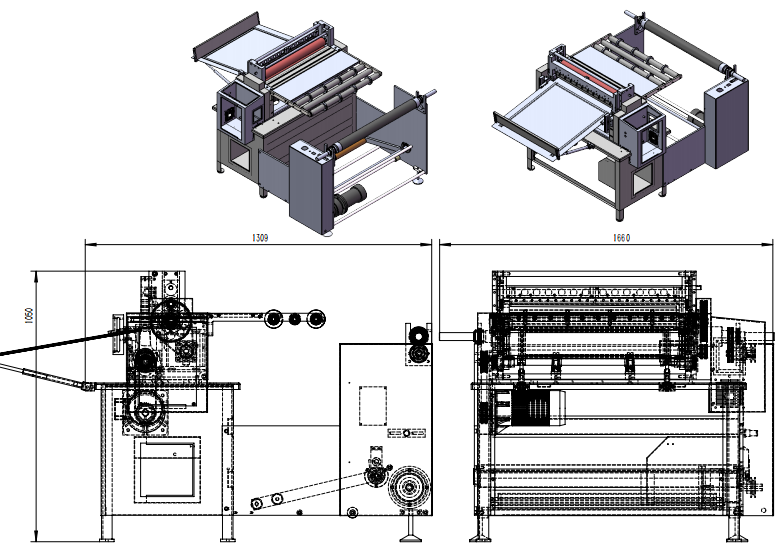

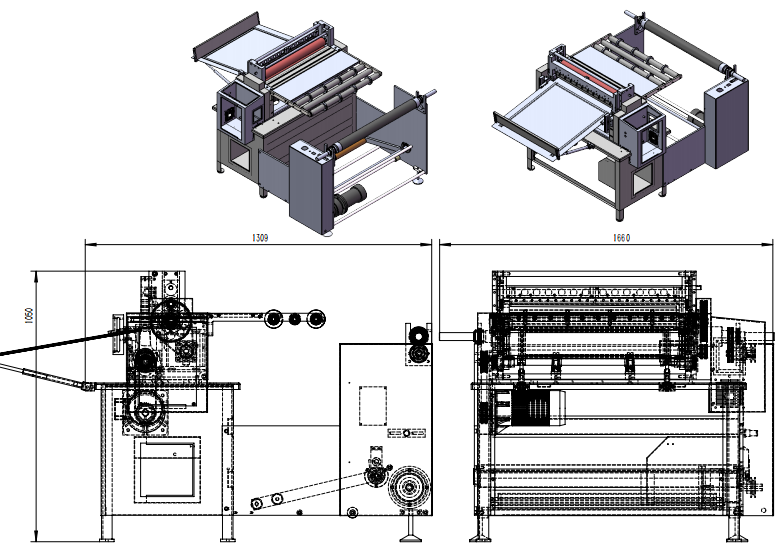

Machine structure

Machine Technical Parameter

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Advantages of roll to sheet cutting machine for PVC

PVC roll to sheet cutting machine is an efficient and accurate cutting equipment, which is widely used in the cutting and processing of PVC sheets, plastic sheets and other materials. The main advantage of the PVC cutting machine is its efficient, precise and reliable cutting performance, which can provide users with sufficient production efficiency and cutting quality assurance. In the following article, we will introduce the features and advantages of PVC roll to sheet cutting machine.

Advantages of PVC roll to sheet cutting machine:

1. Efficient production

The PVC roll to sheet cutting machine has an efficient production capacity, which can complete a large number of cutting tasks in the shortest time, which improves the user's production efficiency.

2. High cutting precision

The PVC roll to sheet cutting machine has a high-precision cutting function, and its cutting accuracy can reach the millimeter level, with good reliability and stability.

3. High reliability

The PVC roll to sheet cutting machine adopts high-quality cutting process and materials, which guarantees its reliability and stability.

4. Easy to maintain

The PVC roll to sheet cutting machine is easy to maintain and easy to replace parts. At the same time, it has the advantages of long life and stability, reduces the cost and time of maintenance, and improves the service life of the whole machine.

Machine shipment

1. Inside with film protection

2. Outside with standard plywood package.