Slitting and rewinding machine is a high-end, precision product that is used in a variety of industries. It is designed to cut and rewind large rolls of material into smaller rolls. This machine has numerous advantages that make it a popular choice for businesses that require high-performance and productivity. Here are some of the benefits of the vrtical slitting and rewinding machine:

1. Efficient operation:

The slitting and rewinding machine is designed to handle large volumes of materials with ease. It can quickly cut and rewind rolls of material in short intervals. This ensures that the production process is efficient and minimizes downtime, leading to increased productivity and profitability.

2. Easy to use:

The machine is user-friendly and easy to operate, making it suitable for both skilled and unskilled workers. It comes with a user manual and easy-to-understand controls that are easy to learn and operate. This also saves time and reduces the need for excessive training and supervision.

3. High precision:

The machine is highly precise, ensuring that the rolls produced are uniform and of high quality. The system is designed with advanced technology that ensures that the final product meets the required specifications. This aspect improves the overall quality of the final product and guarantees customer satisfaction.

4. Versatility:

The slitting and rewinding machine can handle a wide range of materials such as paper, film, foil, and laminates. This makes the machine a suitable tool for businesses that require the flexibility to work with different materials. Additionally, the machine is highly customizable, allowing businesses to tailor it to their specific needs.

Application

The slitting rewinding machine is suitable for slitting and winding such various roll materials as PP,OPP, BOPP, PET, CPP, CPE, PVC, different kind of paper, etc. Can slit and rewind materials according to different requirements.

Slitting machine technical parameters

| Model | LT-1300F |

| Max. unwind mother roll diameter | 600mm |

| Max. unwind mother roll width | 1300mm |

| Paper inner diameter | 76mm |

| Slitting width | 20-1300mm |

| Machine speed | 160m/min |

| Slitting speed | 150m/min |

| Max rewind diameter | 500mm×2 rolls |

| Rewind shaft diameter | 1" ,2" ,3"(standard 3", 2pcs install) |

| Slitting precision | ±0.5mm |

| Voltage | customized |

| Total power | 5.5-10KW |

| Gross Weight | 1000-2500kg |

| Overall dimension | 2.6×1.7×1.5m |

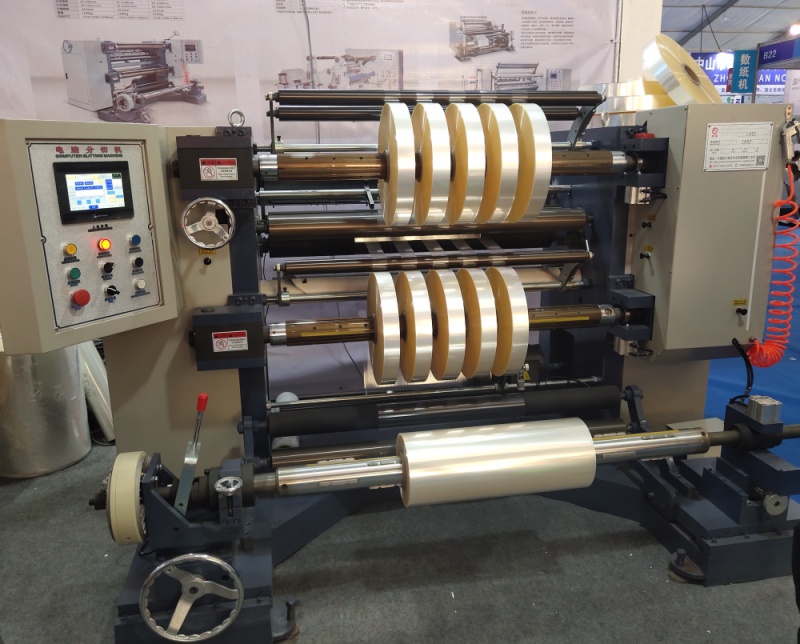

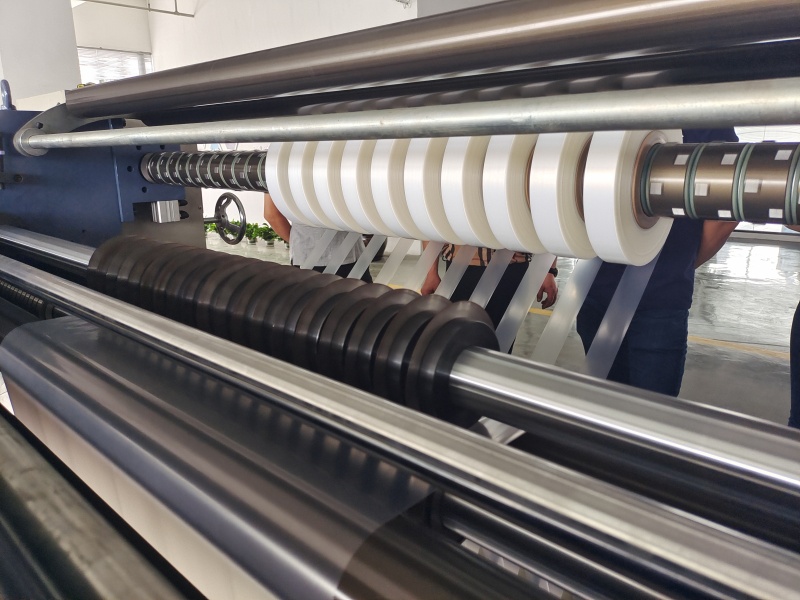

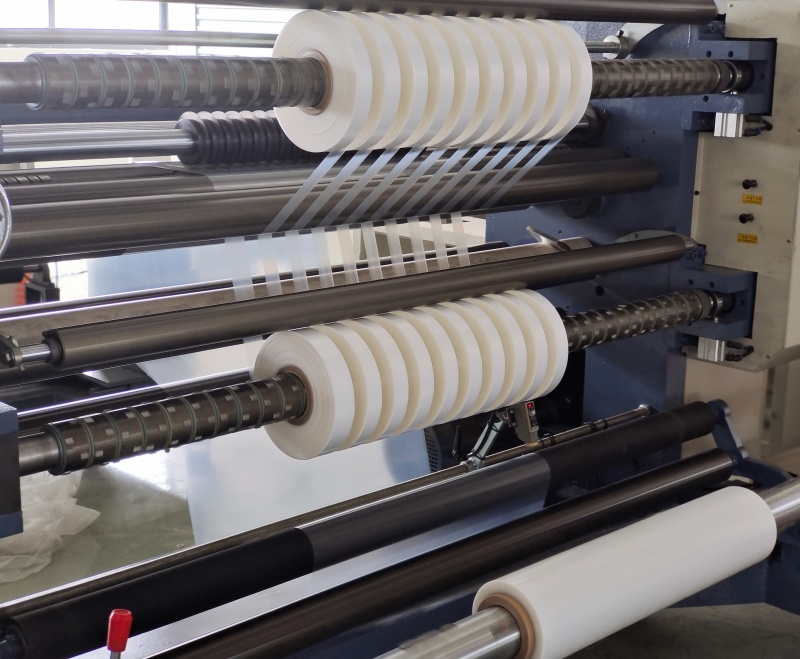

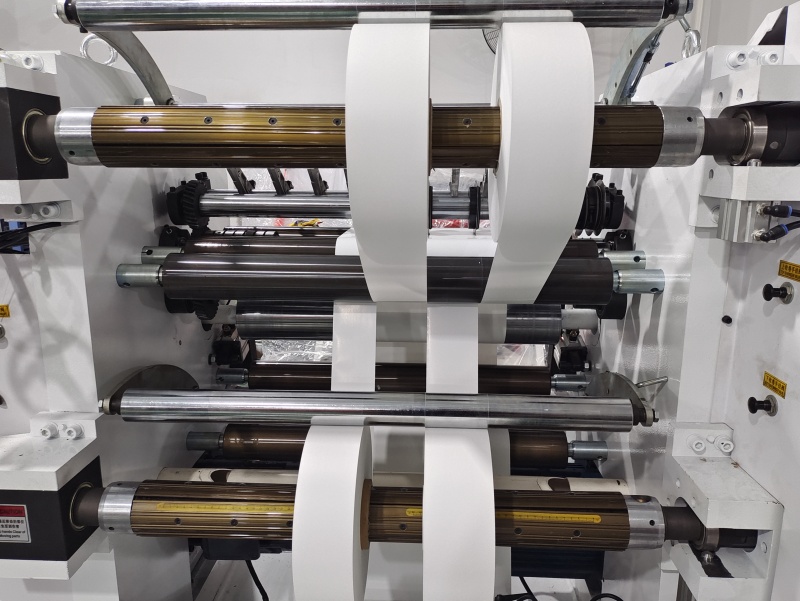

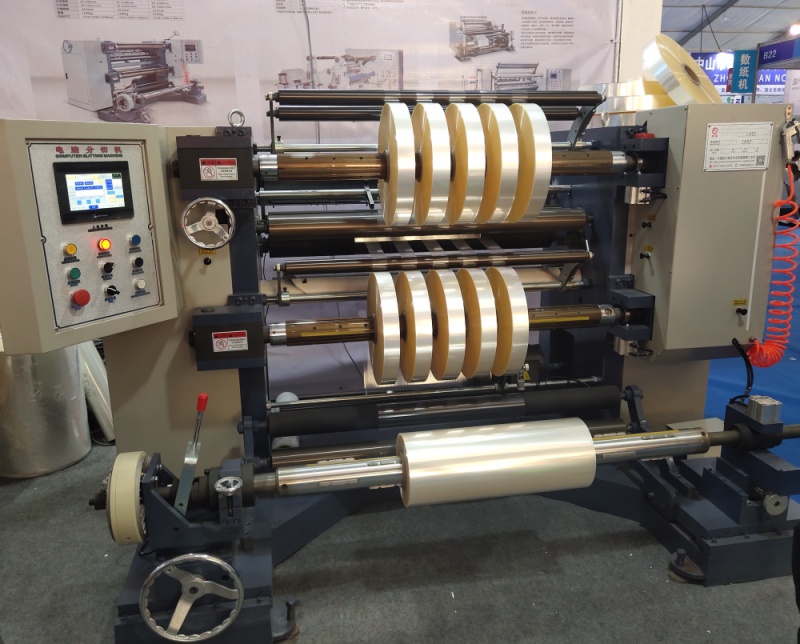

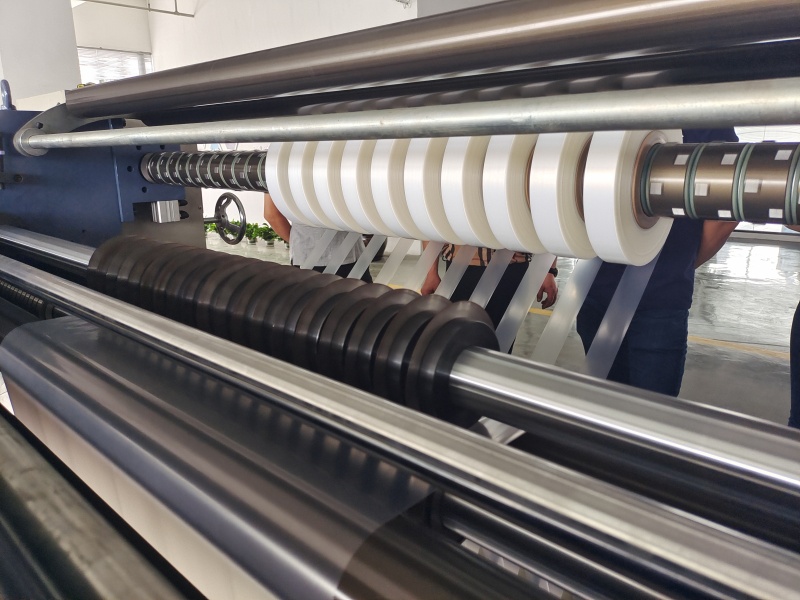

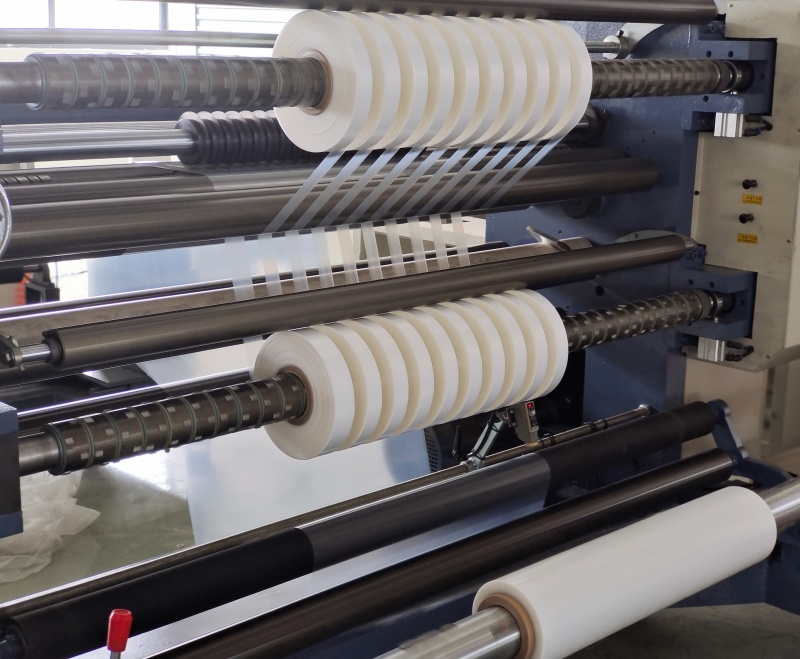

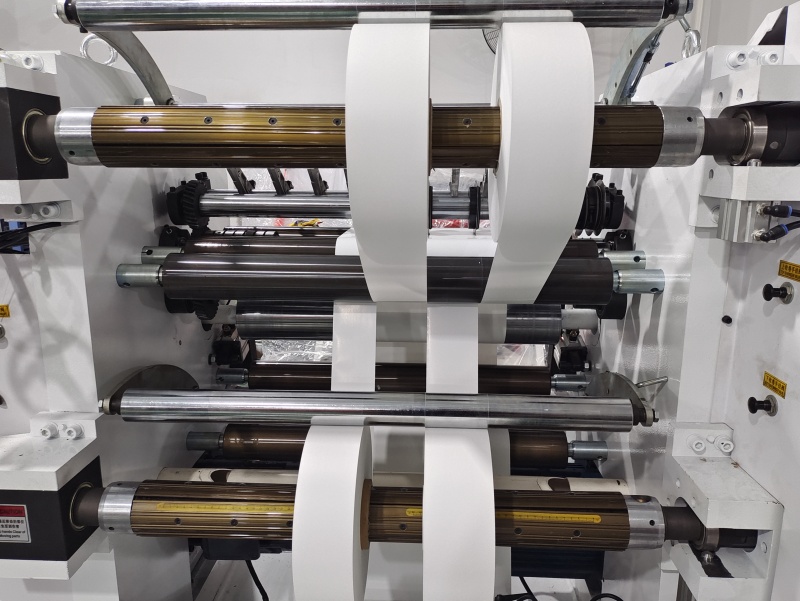

Slitting and rewinding machine photos

Based on good quality of slitting machine, the effect is pretty good. Pls see below photos.

There are options of slitting blades and rewinding shafts.

For slitting blades:

1. Round slitting blades

2. Straight slitting blade

For rewinding shafts

1. standard air shaft

2. Slide spindle