Automatic Nonwoven Slitting Machine with Good Quality

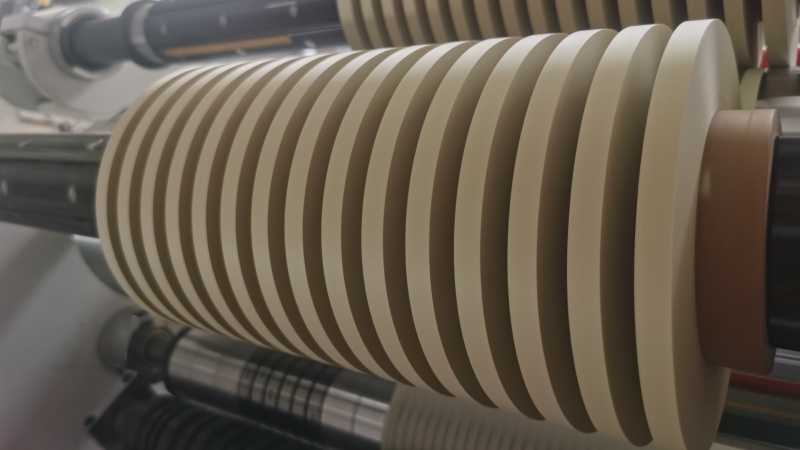

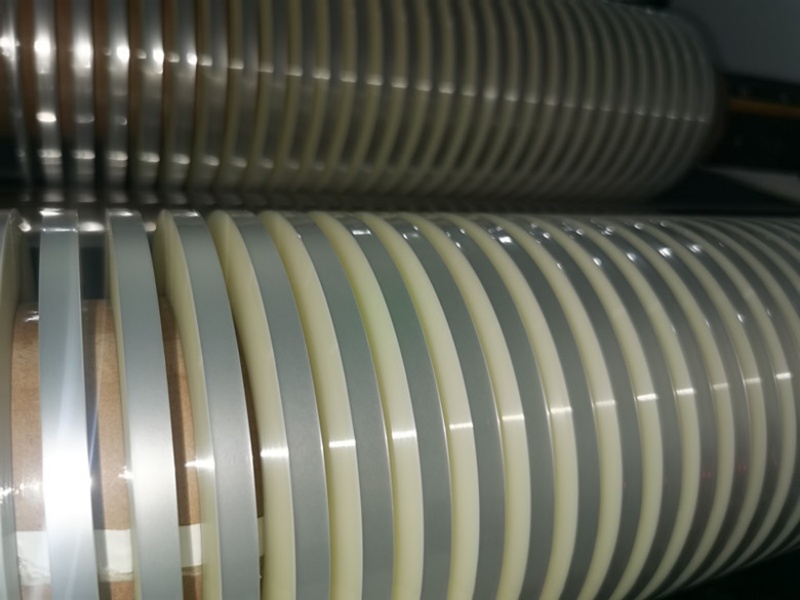

Application

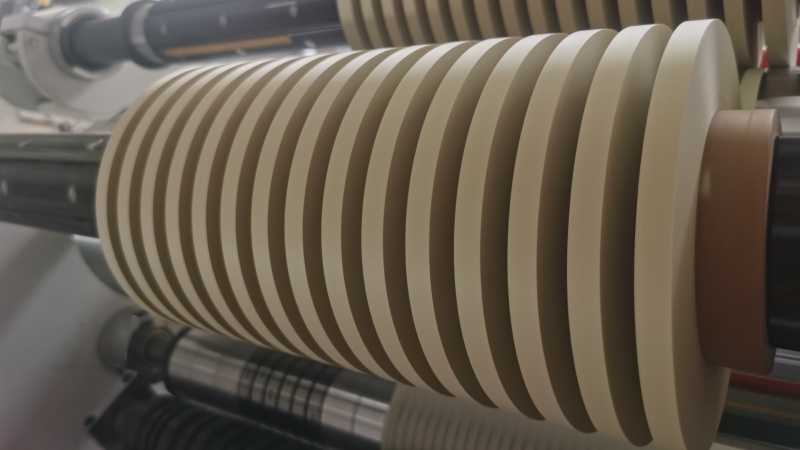

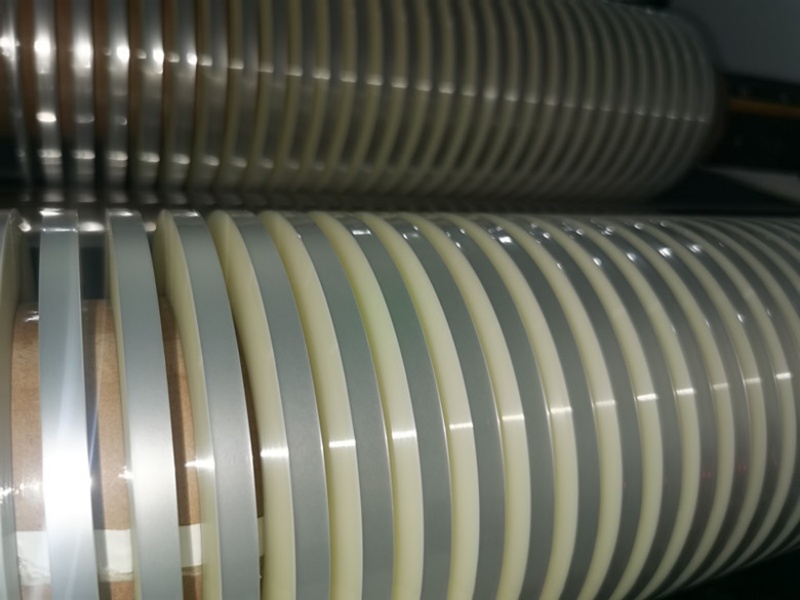

It is suitable for slitting and rewinding all kinds of paper, film, copper foil, aluminum foil and other materials.Such as PVC, PE, PET, adhesive tape,release paper and other materials.

Technical Parameter

Raw material width | 700-1600mm |

Maximum raw material diameter | 1000mm |

reel | Split tension inflatable shaft |

Maximum winding diameter | 600mm |

total power | 5.5-7.5KW |

Minimum slitting width | 5mm |

Slitting speed | 150m/min |

Diameter of unwinding shaft | 3 inch |

Diameter of winding shaft | 3 inch |

Dimensions | 2450×2450×1550mm |

weight | 3000-6000kg |

Machine configuration

1.PLC Control Panel

You can set slitting speed,running length,unwinding and rewinding tension on it. It is very easy for worker to operate the machine.

2. Mitsubishi servo driver and motor

Three Mitsubishi servo motors and servo drivers are used for linkage control with high speed and stable tension.

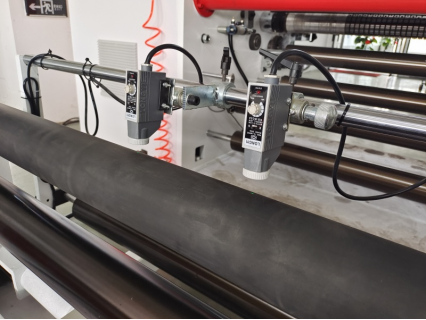

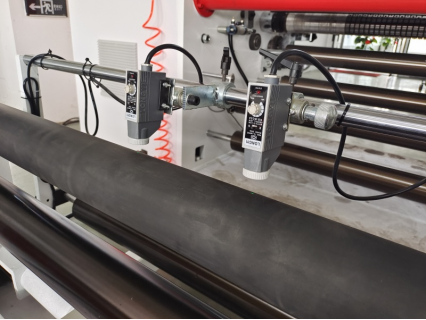

3. EPC Edge/Line position controller

This ultrasonic sensor is used to guide the non neat material.to make sure the slitting rewinding effect is good.Automatic web guide is composed of ultrasonic sensor and one AC electric actuator which moves left or right if the material comes out of the path of the photoelectric eyes.

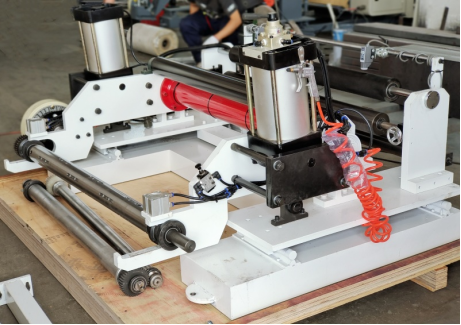

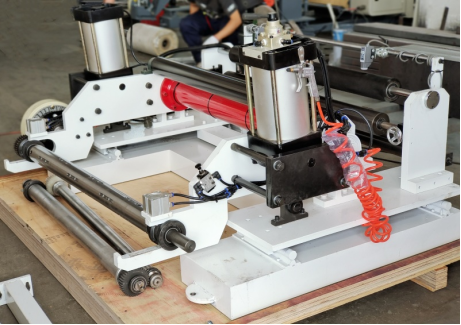

4. Automatic Unwinding Device

Material Unwinding Stand For Slitting Machine, It is customized according to material weight and diameter.