Yes, we can customize solutions according to your exact requirements.

3) What information does the quotation require? Some of the basic information we need is what product do you need to pack what are their dimensions. Additionally, we would need to know the type of packaging you need, the desired output, and area available for our machinery.

4)Do you provide overseas after-sales services? ls it free or extra?

1. For technical training on adjustment and operation of the equipment abroad, the seller shall send technicians to the buyer's factory while the buyer shall be charged for such service cost including round-air ticket, boarding & lodgings, visa fee as well as a daily service fee of USD100.00.

2. For damaged spare parts resulting from quality problems, the seller shall supply the buyer free of charge for replacements within the warranty period. Otherwise, the buyer shall buy parts at their own expense.

5)What does your after-sale service entail? For our customers, our machines are very durable and have a 1-year warranty. Some machines provide remote program upgrade services. Also, after-sales services include maintenance,on-site training, and more.

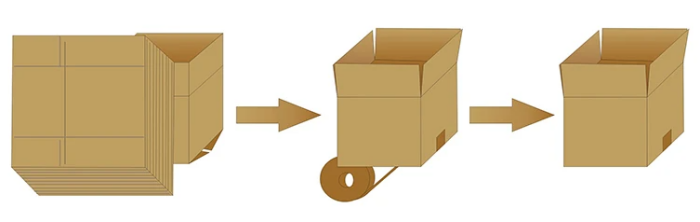

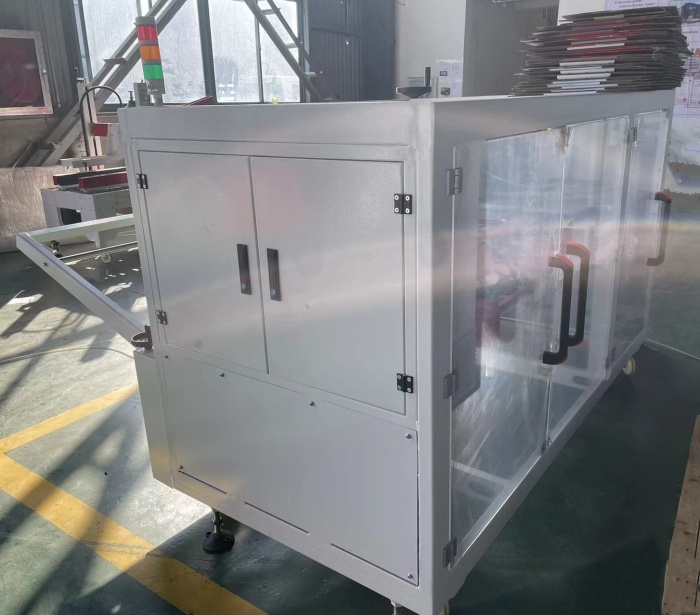

When it comes to packaging, the process of opening and sealing boxes can often be tedious and time-consuming. But, what if there was a solution that could make the process more efficient and streamlined? Enter the fully automatic box opening and sealing machine.

Customized to the exact specifications of the customer, this machine is designed to take the hassle out of packaging. With the ability to open and seal boxes at a rapid rate, it can significantly improve productivity and workflow in any manufacturing or distribution setting.

One of the biggest advantages of the fully automatic box opening and sealing machine is its ability to handle a wide range of box sizes and weights. Whether it’s a small box or a larger one, this machine is equipped to handle the job. Plus, with its user-friendly interface, it’s easy to operate and can be set up to start working in no time.

In terms of efficiency, this machine has a lot to offer. Not only will it significantly reduce the amount of time required for packaging, but it will also help to eliminate errors and ensure that each box is properly sealed and secured. Furthermore, it reduces the need for manual labor which can lead to a much safer working environment.

For businesses looking to streamline their packaging process and improve overall productivity, the fully automatic box opening and sealing machine is an excellent investment. With its high level of customization and advanced capabilities, it’s a machine that can truly make a difference in the way your business operates.

In conclusion, the fully automatic box opening and sealing machine is a customized solution that can help businesses in all industries to improve their packaging process. From reducing time and labor costs to improving efficiency and accuracy, it’s a machine that offers a wide range of benefits. If you’re looking for a way to take your packaging process to the next level, this machine is certainly worth considering.