Automatic box sealing machine is a set of automatic fold and packing machines, that can be used to support the automatic packaging line, automatic up and down sealing tape multi-channel packaging, after the unmanned packaging, high working efficiency, widely adapted to the printing of painted greeting cards, photo albums, photo frames, medicine, electronic daily cosmetics production industry.

Machine parameter

| Product No | LT-02 |

| Carton Size | L200-600mm * W150-500mm * H120-500mm |

| Packing Speed | 15-20 cartons/min |

| Power | 220/380V 50hz/60hz 500W |

| Air Compressing | 6kg/cm2 |

| Air Comsumption | 450NL/min |

| Machine Weight | 220KG |

| Tape Size | 48/60/72mm |

| Machine Size | L1770*W850*H1520mm |

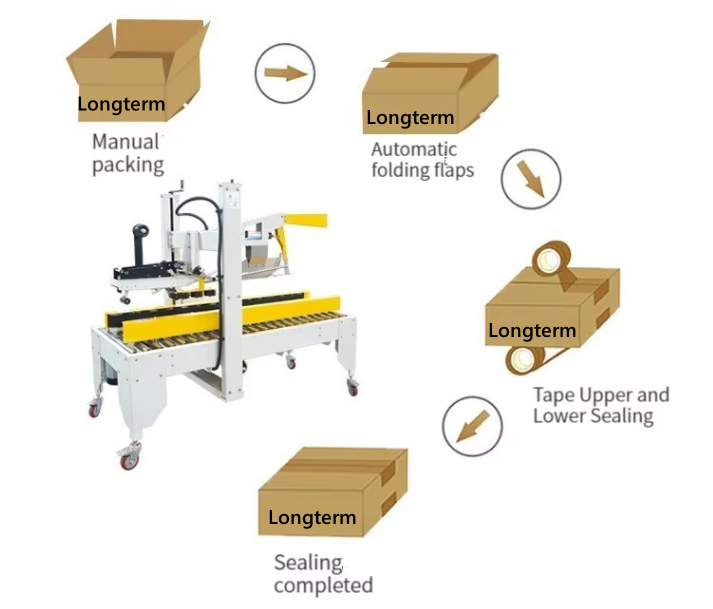

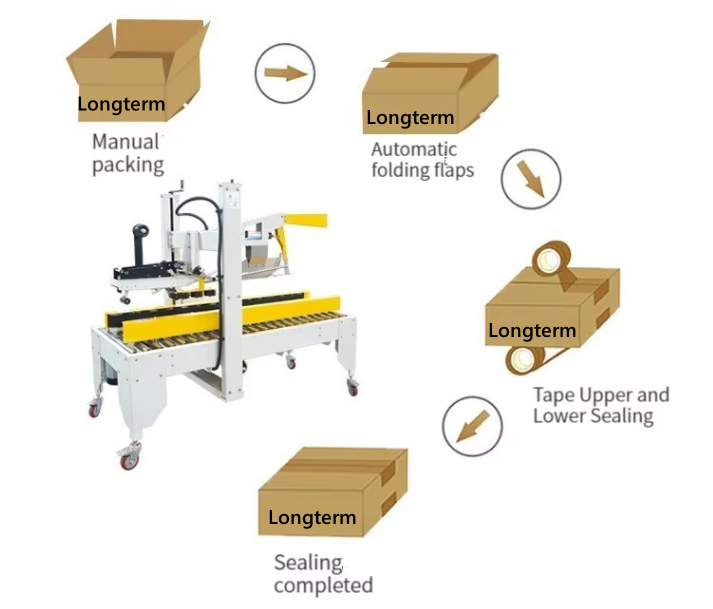

Working process

The development of automatic cartoning machines is a testament to how technological advancements have impacted the manufacturing process. The journey to create an automated solution for cartoning started in the early 1900s when the concept of mass production began to take root. At that time, cartoning was done manually, and it was a time-consuming and labor-intensive process.

The first automatic cartoning machine was developed in the 1930s, and it was a massive breakthrough in the industry. The machine could handle thousands of cartons in an hour, reducing the time needed for the process significantly. Although the machine was rudimentary, it paved the way for further innovation.

In the 1950s, the design of the automatic cartoning machines started to resemble the machines that are used today. The machines were more compact and could handle different sizes of cartons. This made the process more efficient, and companies could meet the demands of a rapidly growing market.

The introduction of computer technology in the 1970s brought a new wave of development to the automated cartoning industry. The machines were integrated with computer technology, which made them more accurate and efficient. Companies could also program the machines to perform various functions, including folding, sealing, and labeling.

The 1990s saw the introduction of robotic cartoning machines. These machines were faster and more precise than their predecessors. They could handle complex cartons, including those with unusual shapes, with ease.

Today, companies can choose from various types of automatic cartoning machines, depending on their needs. The machines are faster, more precise, and efficient than ever before. They can handle different sizes and shapes of cartons, and they can perform various functions, including filling, sealing, labeling, and coding.

In conclusion, the development of the automatic cartoning machine has revolutionized the manufacturing process. It has reduced the time and labor required for cartoning, and it has increased the speed and precision of the process. With the rise of technology, we can only expect that the machines will continue to evolve, making the process even more efficient and cost-effective for companies.