High Speed Slitting Machine for Paper, Film, Foil, non-woven

Automatic Slitting Rewinder Machine: Working Principle

The working principle of the automatic slitting rewinder machine is simple. It involves the use of a rotary cutter that is used to cut the material into desired widths. The material is then passed through a set of rollers that help in rewinding the material into smaller rolls. The machine is equipped with sensors that ensure that the material is cut and rewound with precision.

The first step in the working of the automatic slitting rewinder machine is the loading of the material. The material roll is loaded onto the machine using a hydraulic lift. The roll is then passed through a set of idler rollers, which guide the material towards the rotary cutter. The rotary cutter, which is situated at a certain distance from the idler roller, ensures that the material is cut with precision. The cutter is guided by an electric motor that controls the speed and direction of the cutter.

Once the material is cut into desired widths, the small rolls are passed through a set of rollers that help in rewinding the material into smaller rolls. The machine is equipped with sensors that ensure that the material is rewound with precision. The sensors detect any unevenness in the material, and the machine adjusts itself accordingly.

The automatic slitting rewinder machine is also equipped with a control panel that allows the operator to adjust the cutting and rewinding speed of the machine. The control panel also displays all the necessary information about the machine, such as the material being used, the width of the material being cut, and the speed at which the machine is running.

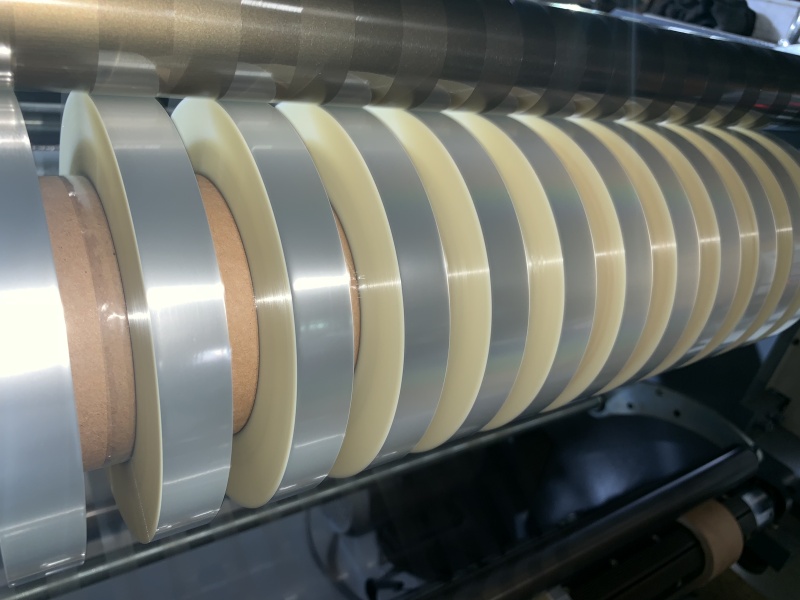

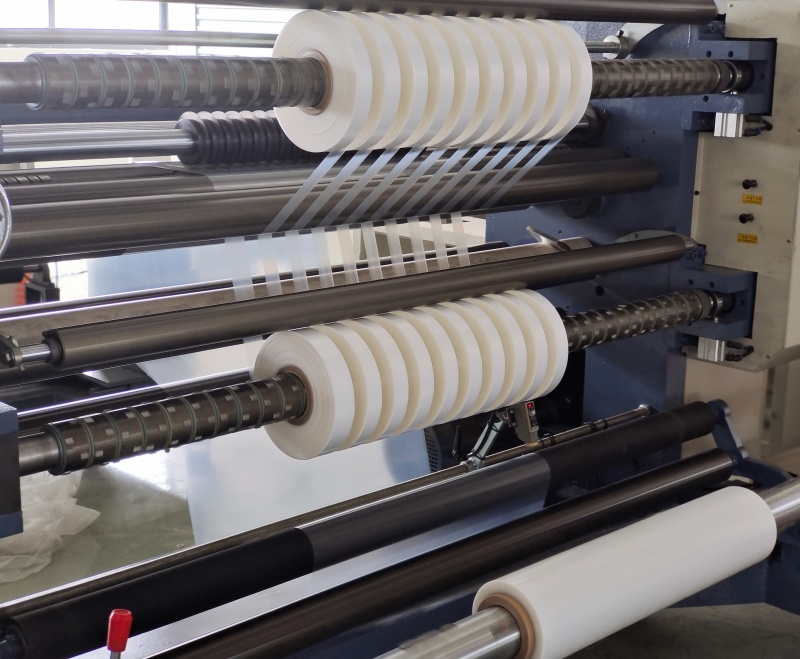

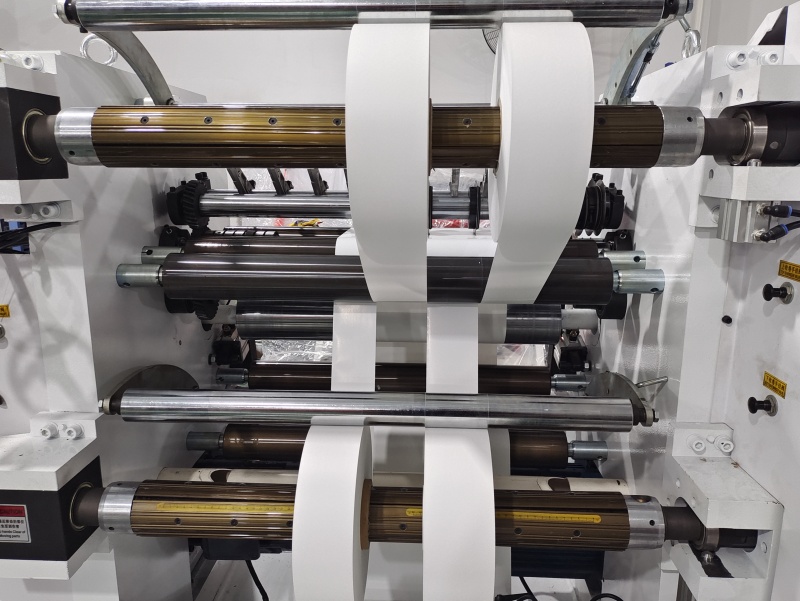

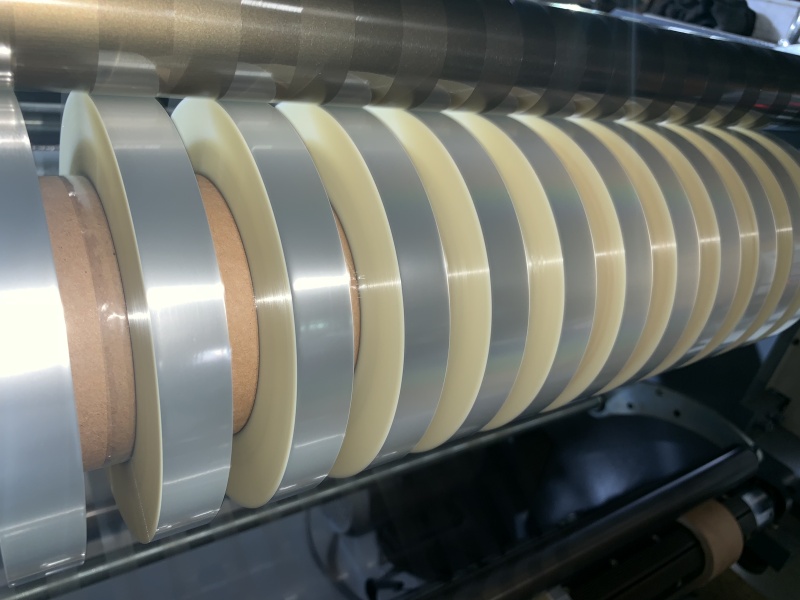

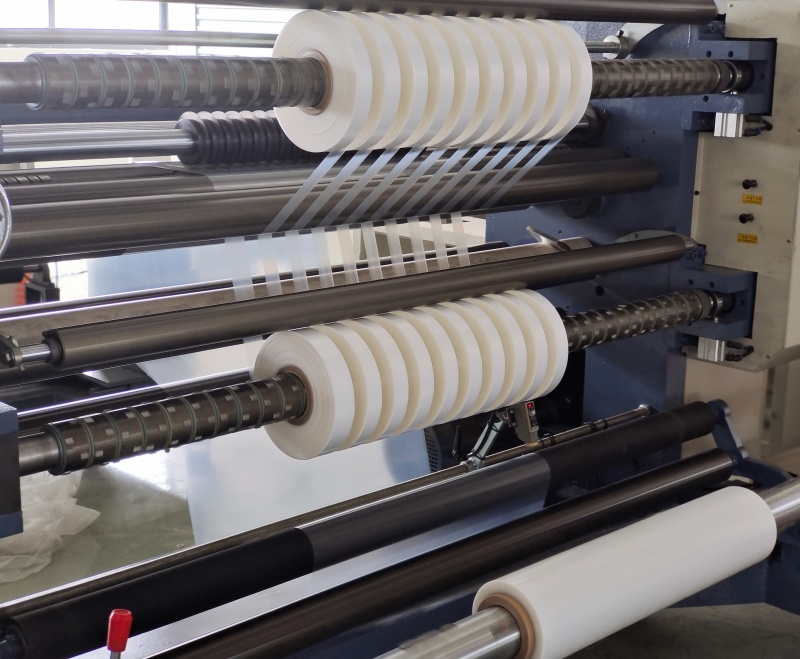

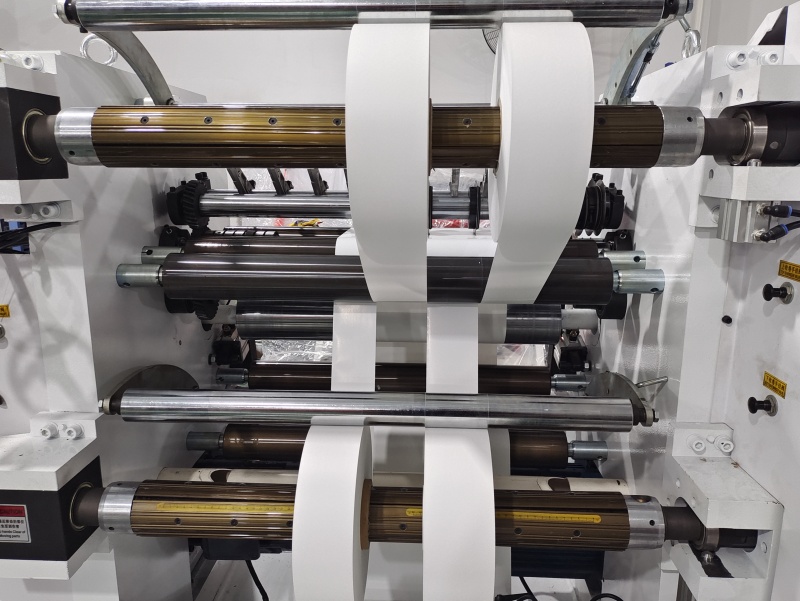

Photos of slitting rewinding machine

Application

This slitting machine is suitable for slitting and rewinding many kinds of roll materials, such as PP, OPP, BOPP, PET, PVC and different kind of paper, kraft paper, food paper, etc.

Slitting rewinding machine technical parameters

| Model | LT-1600F |

| Max. unwind mother roll diameter | 600mm |

| Max. unwind mother roll width | 1300mm |

| Paper inner diameter | 76mm |

| Slitting width | 20-1600mm |

| Machine speed | 160m/min |

| Slitting speed | 150m/min |

| Max rewind diameter | 500mm×2 rolls |

| Rewind shaft diameter | 1" ,2" ,3"(standard 3", 2pcs install) |

| Slitting precision | ±0.5mm |

| Voltage | customized |

| Total power | 5.5-10KW |

| Gross Weight | 1000-2500kg |

| Overall dimension | 2.6×1.7×1.5m |

Based on good quality of slitting machine, the effect is pretty good. Pls see below photos.

There are options of slitting blades and rewinding shafts.

For slitting blades:

1. Round slitting blades

2. Straight slitting blade

For rewinding shafts

1. standard air shaft

2. Slide spindle