Bread bag, packaging bag making machine

Machine features

The machine is suitable for heat sealing and cutting BOPP, OPP heat shrink film and other materials, and is an ideal equipment for making sock bags, towel bags, bread bags, and jewelry bags. This machine is equipped with computer fixed length, photoelectric tracking, stable performance, and fast speed. Equipped with automatic punching, hot lace and other functions.

Photo of application bags

Machine technical parameter

| Item Number | LT-600ZD | LT-800ZD | LT-1000ZD |

| Cutting & sealing width | 580mm | 780mm | 980mm |

| Cutting & sealing length | 720mm | 720mm | 720mm |

| Bag making speed | 40-240pcs/min | 40-240pcs/min | 40-240pcs/min |

| Machine power | 3KW | 4KW | 5KW |

| Machine weight | 700kg | 850kg | 950kg |

| Machine dimension | 3600*1200*1700mm | 3600*1400*1700mm | 3600*1600*1700mm |

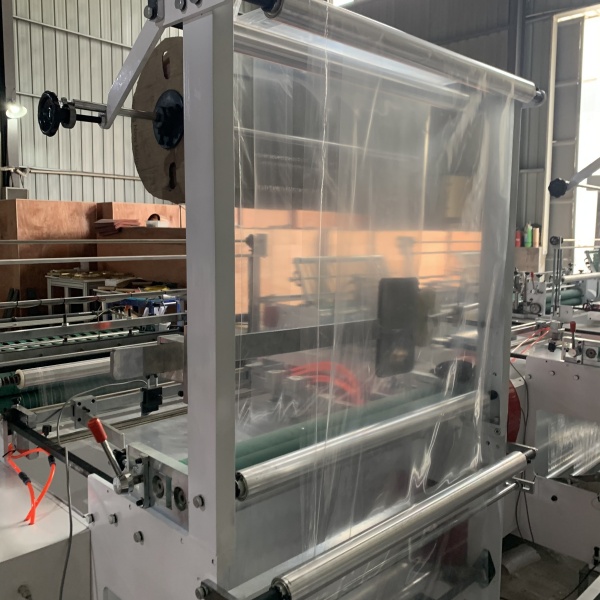

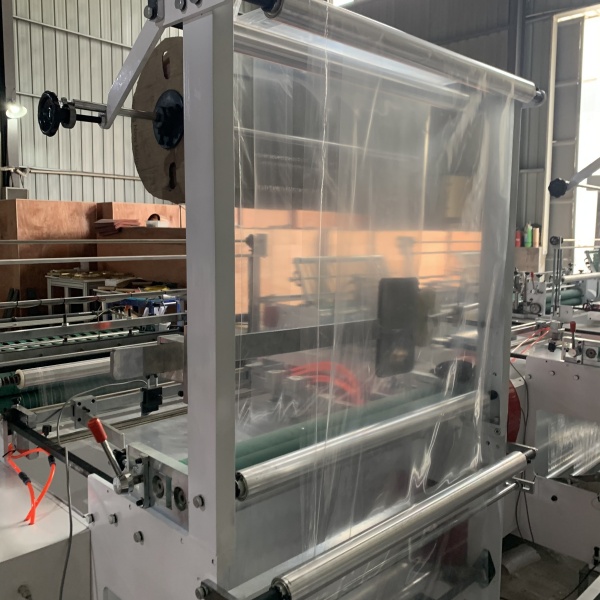

Machine details

unwinding device (different options )

feeding device

heating cutting

Advantages of plastic bag making machine

Packaging bag making machines are gaining fast popularity in various industries across the globe. These machines empower businesses with a quick and efficient way to produce packaging bags of many possible types. Often, they come in fully-automatic models that can perform a range of functions, such as bag-making, printing, filling, and sealing. In this article, we will provide you with an overview of the advantages of packaging bag making machines.

1. Improved efficiency and speed

One of the main benefits of packaging bag making machines is the speed at which they operate. These machines offer improved efficiency and speed, dramatically reducing time spent on manual cutting and welding. As a result, manufacturers can produce more bags in less time than ever before, allowing them to meet larger and more complex customer demands.

2. Cost-effective production

Packaging bag making machines can save businesses big money by cutting down on labor costs. Automated machine operations minimize the resources required to carry out tasks, decreasing the need for human labor. As a result, businesses can reduce their overhead costs and reinvest some of that money back into the company.

3. Consistent quality

Another significant advantage of packaging bag making machines is the ability to produce even and consistent results every time. When bags are made manually, errors and inconsistencies in shape, size, and material are inevitable. However, with automatic bag-making machines, the process is precise, and therefore, every package is consistent, of top-quality, and ideal for storing various merchandise.

4. Customizable and versatile

Packaging bag making machines can produce bags of different sizes, styles, and shapes. The machines can be adjusted to produce unique and customized bags according to your requirements. This makes the machines highly versatile – all you need is to pick a specific model that meets your bag making needs.

5. Environmentally friendly

Most of the modern packaging bag making machines come equipped with eco-friendly features. They use environmentally friendly materials to produce bags that can be safely disposed of, recycled, and reused. Consequently, the machines help businesses promote environmentally sustainable practices.

In conclusion, packaging bag making machines are highly advantageous to businesses. They not only make packaging more efficient, but they can also reduce production costs, produce consistent quality, and help preserve the environment. By investing in a packaging bag making machine, businesses can make their packaging processes simpler, quicker, and more productive.