Automatic shrink sleeve sheeting machine

Why Choose An Automatic Roll to Sheet Cutting Machine?

1. High efficiency: The roll to sheet cutting machine can cut paper quickly and accurately, improving production efficiency.

2. High precision: The reel to sheet cutting machine has a high-precision cutting function, which can achieve precise cutting of paper of various specifications.

3. High degree of automation: The reel to sheet cutting machine can automatically complete the process ofcutting, feeding, and collecting without manual intervention, which greatly improves the work efficiency and safety.

4. Wide applicability: The reel to sheet cutting machine is suitable for various types of paper, including soft, hard, double-sided coating, etc.

5. Resource saving: The cutting accuracy of reel to sheet cutting machine is high, which can effectively avoid the waste of paper due to inaccurate cutting, thereby saving resources.

6. Good environmental protection: The reel to sheet cutting machine adopts advanced technology and equipment, which can achieve low energy consumption and low pollution production mode, and meet the requirements of environmental protection.

Features of shrink sleeve sheeting machine

1. The max cutting width option: 360, 500, 600, 700, 1000mm.

2. Cutting Precision: 0.03mm

3. Material thickness: 0.5mm-20mm (according to different materials)

4. Cutting speed: 100cut/min;

5. Both kiss-cut and complete cut are available; Complete cut is for standard machine, and kiss-cut is an option;

6. A conbination of PLC and servo motor.

7. Eye mark device for optional

8. An air shaft as the loading shaft;

9. Two accessories, static eliminator and conveyor belt, for you to choose

10. Automatic unwinding function;

Machine Parameters

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Machine photos

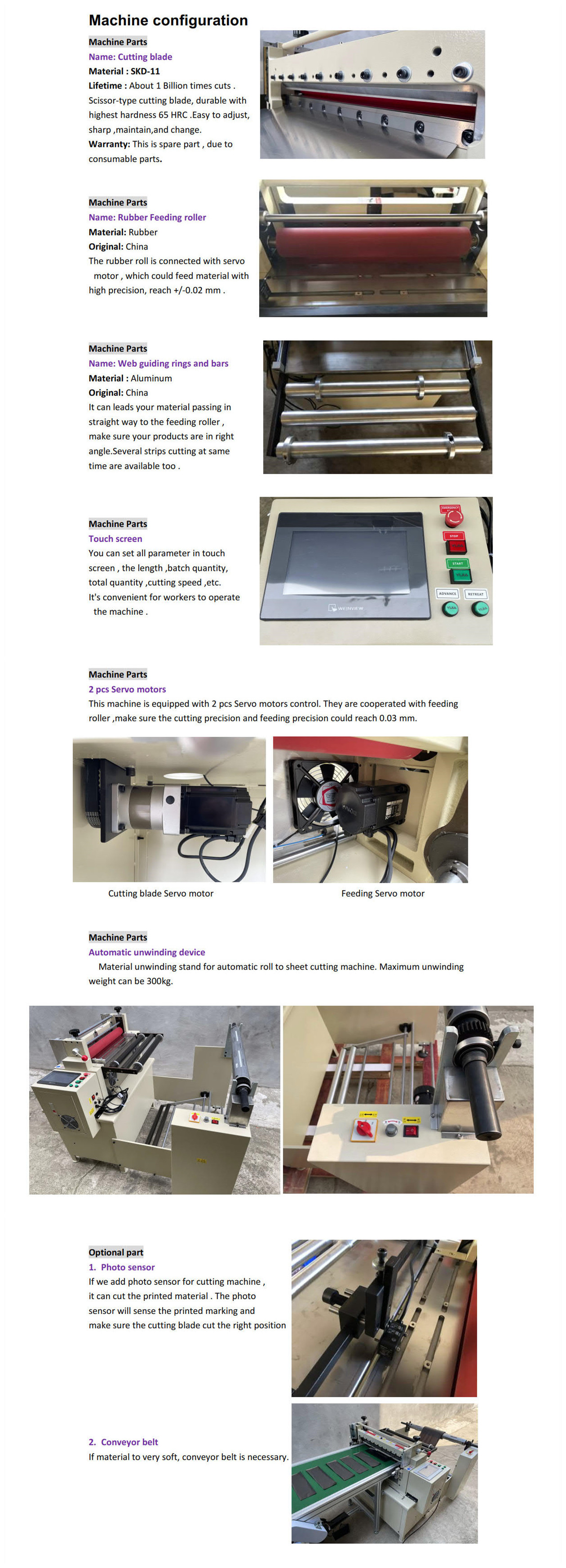

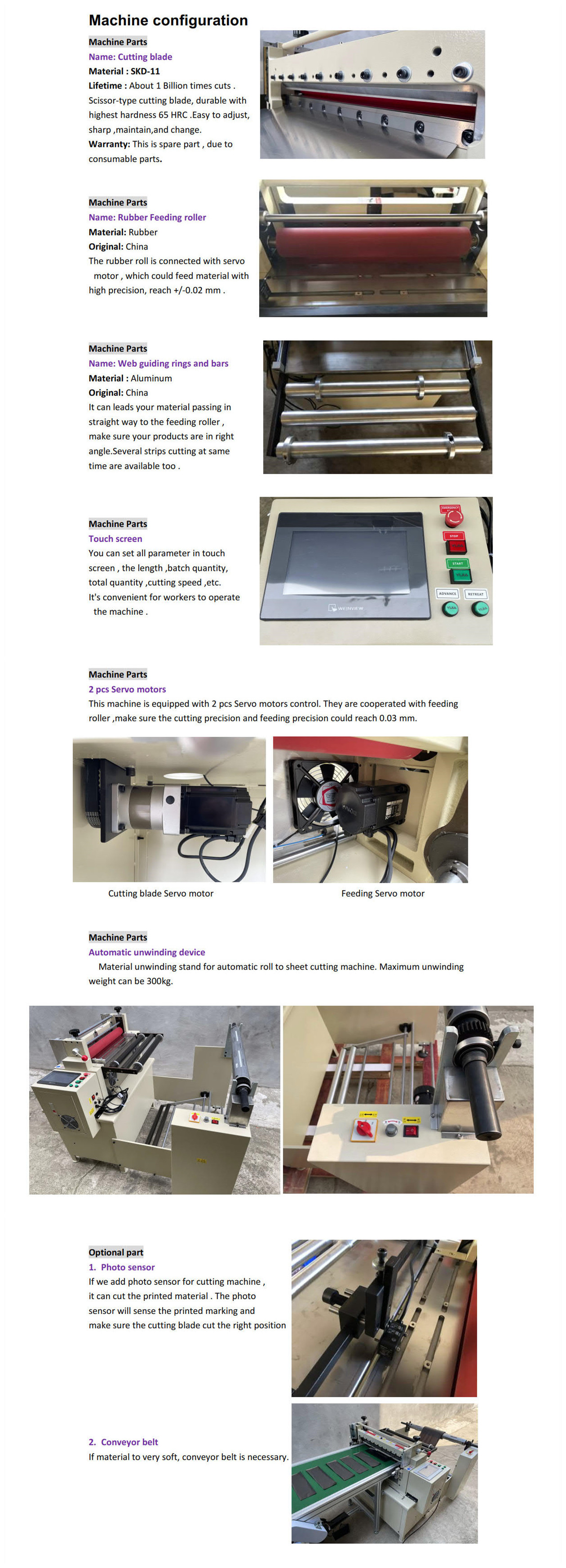

Machine configuration

CE certificate

Comments from our clients