Automatic pvc tape slitting rewinding machine

Application

This slitting machine is suitable for slitting and rewinding many kinds of roll materials, such as PP, OPP, BOPP, PET, PVC and different kind of paper, kraft paper, food paper, etc.

Slitting machine technical parameters

| Model | LT-1300F |

| Max. unwind mother roll diameter | 600mm |

| Max. unwind mother roll width | 1300mm |

| Paper inner diameter | 76mm |

| Slitting width | 20-1300mm |

| Machine speed | 160m/min |

| Slitting speed | 150m/min |

| Max rewind diameter | 500mm×2 rolls |

| Rewind shaft diameter | 1" ,2" ,3"(standard 3", 2pcs install) |

| Slitting precision | ±0.5mm |

| Voltage | customized |

| Total power | 5.5-10KW |

| Gross Weight | 1000-2500kg |

| Overall dimension | 2.6×1.7×1.5m |

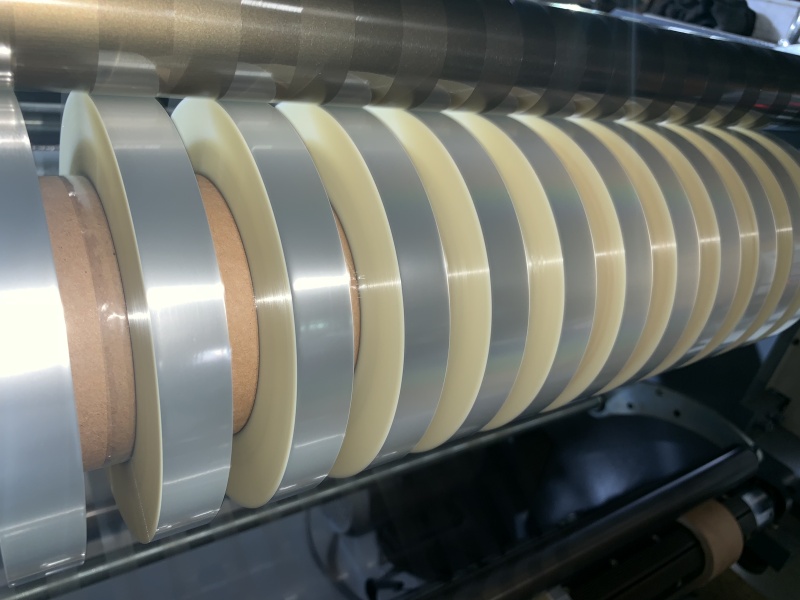

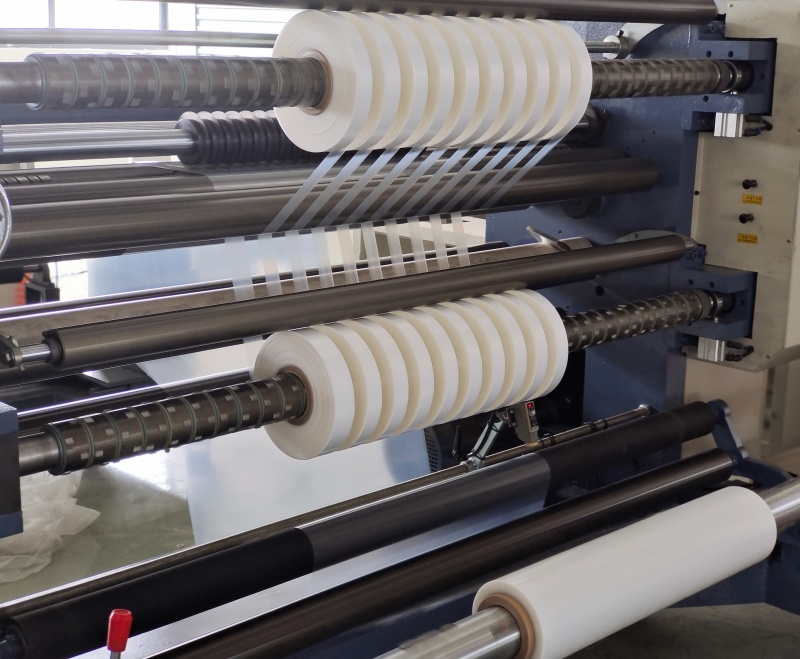

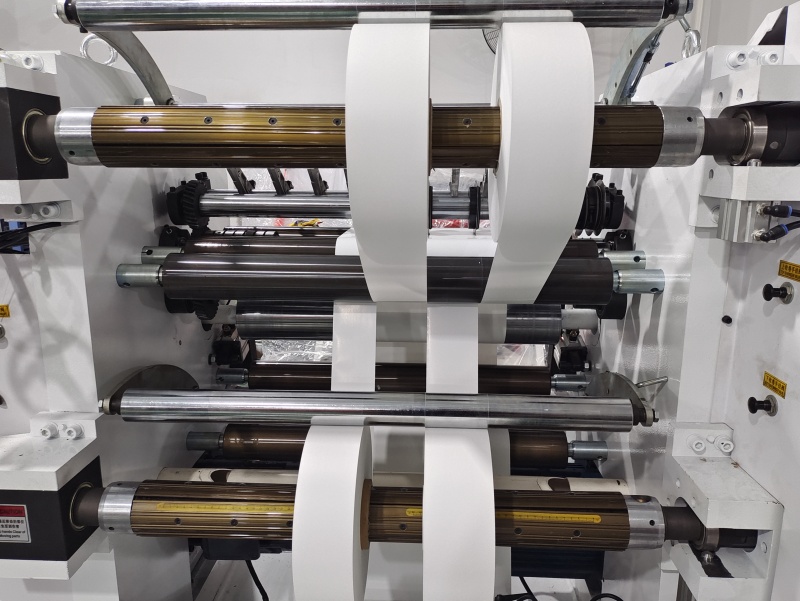

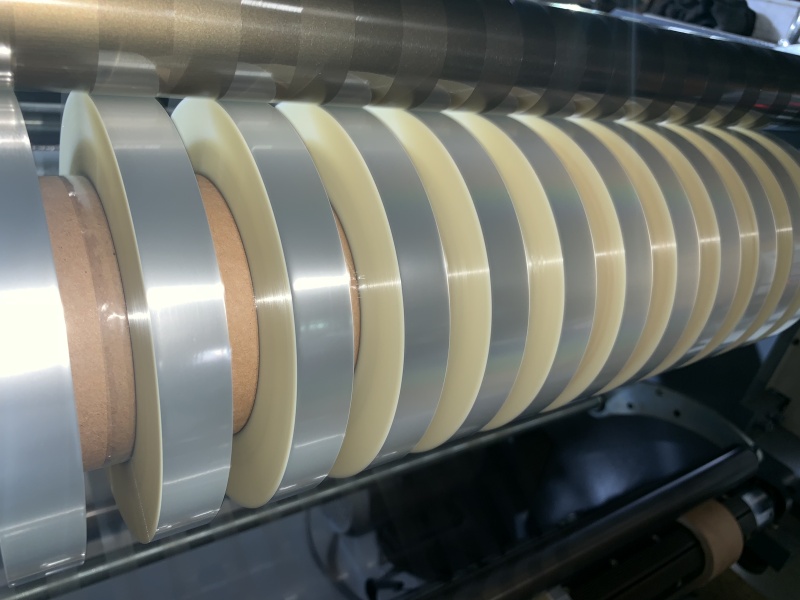

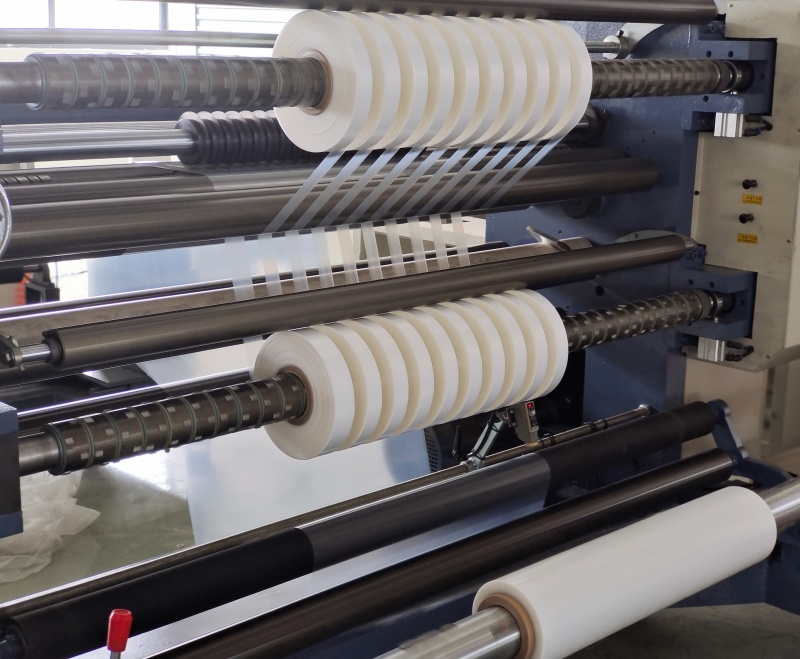

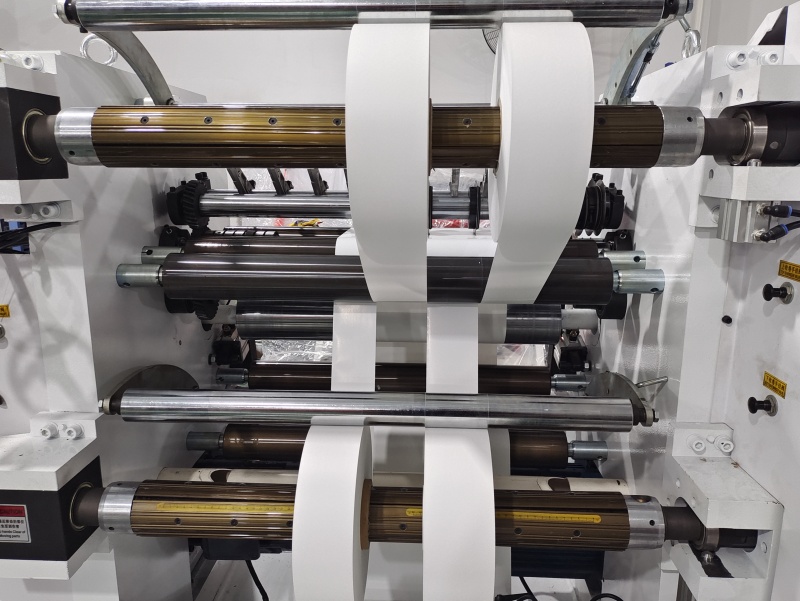

Based on good quality of slitting machine, the effect is pretty good. Pls see below photos.

There are options of slitting blades and rewinding shafts.

For slitting blades:

1. Round slitting blades

2. Straight slitting blade

For rewinding shafts

1. standard air shaft

2. Slide spindle

Automatic slitting and rewinding machine is an essential equipment for paper, film, non-woven fabric, and other industries. This machine is designed to process large roll materials into smaller rolls with specific sizes or widths. It has various functions to meet different requirements and is widely used in the production of packing materials, printing materials, adhesive tapes, and so on.

The automatic slitting and rewinding machine is a fully automated device that can operate at a high speed. It has a stable performance, high precision, and great flexibility. The machine can process materials with a thickness range of 0.012mm to 3mm, and a width range of 300mm to 2500mm. It can handle different materials, including paper, film, non-woven fabric, aluminum foil, and various other materials.

The automatic slitting and rewinding machine is equipped with several functional components, including a feeding system, a slitting system, a rewinding system, a tension control system, and a waste discharge system. The feeding system is used to load the roll material onto the machine, and the slitting system is to cut the material into small rolls with desired widths. The rewinding system is to rewind the smaller rolls, and the tension control system is to maintain the tightness of the material during the process. The waste discharge system is to remove the excess or faulty materials from the machine.

The machine is operated through a user-friendly touch screen panel, where the user can adjust the parameters easily. It has a high degree of automation, which reduces the need for manual labor and increases efficiency. The machine also reduces the risk of damage to the materials and ensures a consistent quality of the output.

The automatic slitting and rewinding machine is an advanced equipment that can meet the production needs of various industries. It has high accuracy, high efficiency, and is easy to operate. With the continuous improvement of technology, it will become more intelligent, more automated, and more functional, making it an indispensable machine for materials processing.

To sum up, the automatic slitting and rewinding machine is a versatile and essential equipment for the materials processing industry. It has multiple functions, including feeding, slitting, rewinding, tension control, and waste discharge, and can handle various materials and specifications. It is automated, intelligent, and efficient, which greatly improves the production efficiency and product quality.