Automatic carton erector

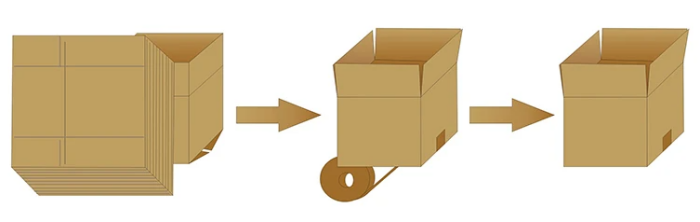

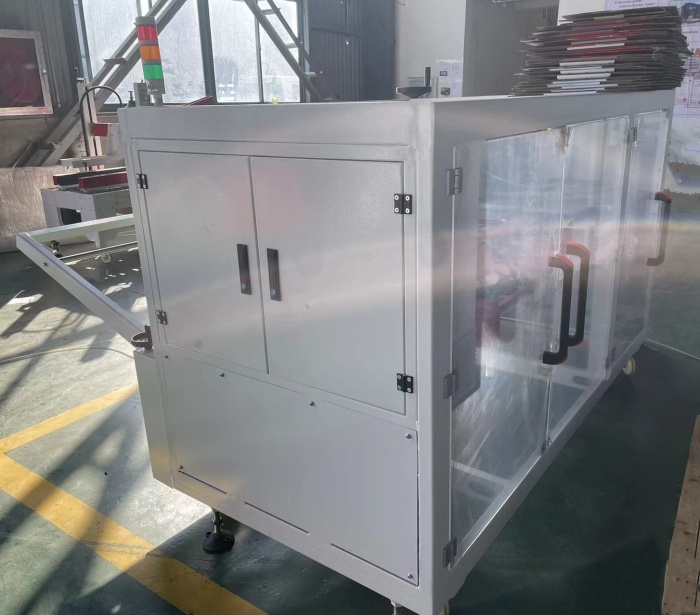

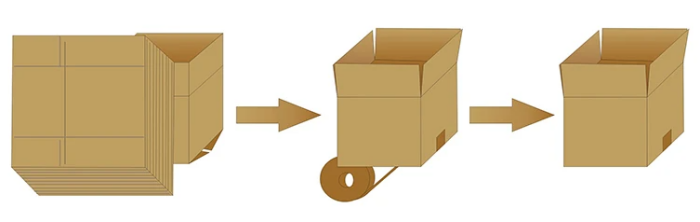

Automatic carton erector can finish the work of carton opening, shaping, folding and sticking adhesive tapes. Equipped with our consistency system, it runs precisely and reliably. This machine provides extremely secure sealing effect, without tape slipping problems. Hot melt glue system is optional. It is widely used with our carton sealer, carton packer, weighting system, strapping machine and conveyor system accordingly. Pls see below photo.

Product Paramenters

Product No | LT-450K |

Carton Size | L200-450mm * W150-400mm * H100-350mm |

Packing Speed | 8-12 cartons/min, 10-18 cartons/min |

Machine Size | L2100*W1900*H1450mm |

Power | 220/380V 50hz/60hz 500W |

Air Compressing | 6kg/cm2 |

Air Comsumption | 450NL/min |

Machine Weight | 520KG |

Tape Size | 48/60/72mm |

Table Height | 600mm |

Machine Direction | Right to left |

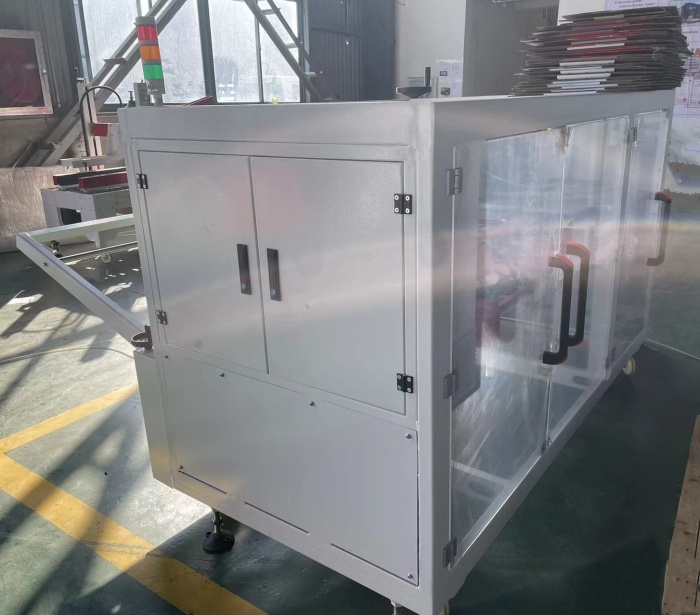

Machine photos

Machine details

NO.1 Touch screen

NO.2 PLC Program Control

NO.3 Pneumatic Components

The Development Process of Fully Automated Box Openers

With the rise of e-commerce and the increasing demand for fast and efficient package delivery, the development of fully automated box openers has been on the rise. In this blog, we will explore the history and evolution of this technology.

Initially, box openers were manually operated devices that required the user to use a blade or scissors to open packages. However, with the rise of e-commerce and the increase in package volumes, manual box opening became an inefficient process that led to slowed delivery times and an increase in packaging waste.

The first automated box opening machines were developed in the early 2000s. These machines utilized sensors and software to identify package dimensions, cut the tape, and open the box in a matter of seconds. However, these early machines were expensive and required a significant amount of maintenance.

Over the past decade, advancements in technology have led to the development of more efficient and cost-effective machines. Today’s fully automated box openers utilize state-of-the-art sensors, cameras, and robotics to quickly and accurately identify package dimensions, cut the tape, and open the box with minimal human interaction.

These machines are designed to work in warehouses and distribution centers, where they can handle high volumes of packages with consistent accuracy. They not only increase efficiency and reduce packaging waste, but they also improve worker safety by decreasing the need for manual box opening.

In addition to their practical benefits, fully automated box openers are also environmentally friendly. By reducing the need for excessive packaging materials, they help to reduce the carbon footprint of the logistics industry and contribute to the overall effort to create a more sustainable supply chain.

In conclusion, the development of fully automated box openers has been a significant advancement in the world of logistics. From manual box opening to the latest in robotic technology, this technology has come a long way and is poised to continue to evolve and improve in years to come.